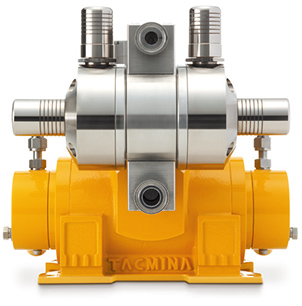

Smoothflow Pumps

In addition to the basics like precision and Functionality, our pumps are also easy to use, safe, and easy to maintain. We give you everything you could ever want from a pump.

-

Excellent Flow Rate Accuracy

-

Gentle on Fluids

-

Capable of Handling a Wide Variety of Liquids

-

Easy to Control

-

No Foreign Substances

-

Capable of Long Distance Transfers

-

Easy Maintenance

No Pulsation

Boasting excellent flow accuracy, this reciprocating pump includes a unique mechanism that produces a continuous, constant flow with no pulsation. The precision of the Smoothflow Pump even meets the strict requirements of cutting-edge processes such as thin film coating and flow synthesis.

[ Related Use Cases ]

No Damage Caused by Slurry

The lack of sliding components in the liquid end part helps prevent various problems, including particle biting and part wear. Pumps can be customized according to various requirements such as the specific gravity and size of particles, making it possible to transfer liquids that would be difficult with conventional systems.

[ Related Use Cases ]

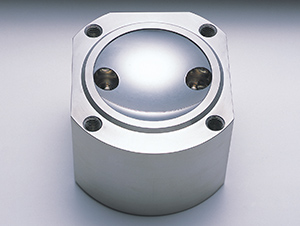

No Leaks

The completely sealed structure does not include any shaft seals, eliminating the need to worry about liquid leakage and ensuring safe transfer even of dangerous chemicals. This also eliminates the need for troublesome tasks such as tightening adjustment.

[ Related Use Cases ]

TCO Saving

With virtually no part wear, Smoothflow Pumps maintain their like-new performance capabilities for a long time. This not only reduces expenses for replacing consumables, overhauling, and performing other tasks, but also reduces the total cost of ownership (TCO).The TCO is the total expenditure amount—from purchase to disposal—required for an asset such as a specific device. This total cost includes not only the initial cost but also invisible costs such as labor and outsourcing expenses for maintenance and operation.

[ Related Use Cases ]

Excellent Flow Rate Accuracy

The non-return mechanism incorporated in Smoothflow Pumps ensures excellent metering characteristics and reproducibility. This ensures a fixed supply amount even when the discharge-side pressure fluctuates.

[ Related Use Cases ]

Gentle on Fluids

Because the transfer liquids are not agitated, sheared, or subject to frictional heat, deterioration-free transferring even of delicate liquids is possible. Liquids also do not come into contact with outside air, preventing problems such as oxidation, curing, and generation of air bubbles.

[ Related Use Cases ]

Capable of Handling a Wide Variety of Liquids

Smoothflow Pumps are capable of transferring a wide range of liquids, from water-like liquids to high-viscosity and high-concentration slurry liquids. TACMINA also offers pumps with high durability depending on the nature of the liquid, including corrosive liquids, organic solvents, and high-temperature liquids.

[ Related Use Cases ]

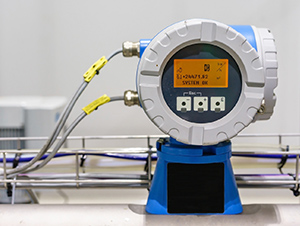

Easy to Control

The continuous, constant flow with no pulsation makes control possible using a flow meter. With high responsiveness and the ability for even, accurate discharging of the specified amount even with a low flow rate or a high flow rate, flow proportion and concentration proportion control is simple and reliable.

[ Related Use Cases ]

No Foreign Substances

Smoothflow Pumps do not include any sliding components in the liquid end part, eliminating the need to worry about wear dust becoming mixed in with transfer liquids. In addition, the pumps are easy to clean with no shaft seals or other narrow gaps, minimizing the risk of cross contamination even when replacing transfer liquids.

[ Related Use Cases ]

Capable of Long Distance Transfers

The elimination of pulsation minimizes piping vibration and pressure loss, so there’s no need for an air chamber. Even when transferring over long distances and with high-pump-head conditions, the ability to use small-bore piping reduces costs while also ensuring safe liquid transfer.

[ Related Use Cases ]

Easy Maintenance

Disassembly and assembly is easy using only general-purpose tools, ensuring the same performance after assembly as was enjoyed before disassembly. In addition, with fewer consumable parts and a longer service life, maintenance frequency and task times can be drastically reduced.

[ Related Use Cases ]

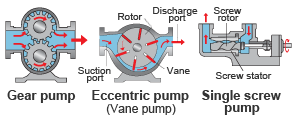

Smoothflow Pumps Versus Conventional Pumps

| Smoothflow Pumps |

|

|---|---|

| Diaphragm Pumps | Conventional diaphragm pumps have advantages over other pump designs such as accurate metering and no leakage. However, due to the general design "pulsation" occurs, which leads to vibration, noise and other issues. |

| Diaphragm Pump + Air Chamber | A common method for suppressing pulsation in conventional diaphragm pumps is to use an air chamber or other pulse-reducing devices. However, using such a device often causes problems such as the lack of output responsiveness and the cost and effort required for cleaning and maintaining the device. |

| Rotary Positive Displacement Pump |

Rotary positive displacement pumps typically offer pulse-free, continuous flow. However, friction causes the mechanical seal and packaging to wear which leads to performance issues and fluid contamination such as leakage. |

Pump Problems? Smoothflow Is the Answer!

Do you have problems or are unhappy with the pump you currently use - leakage, contamination, fluid deterioration, or lack of ease in maintenance?

Smoothflow is the answer!

- I would like to stabilize my long-distance transfer.

- I would like to uniformly mix fluids.

- I would like to transfer high viscosity fluids without changing the chemistry.

- I would like to transfer a slurry without shear.

- I would like to accurately meter my fluid transfer.

- I would like to improve my spraying process precision.

- I would like to resolve my filtration issues.

- I would like to simplify the proportional flow rate control.

- I would like to improve the coating liquid supply.

- I would like to stabilize the supply to the disperser.