Use CasesImproving quality by preventing metal contamination, making the film thickness uniform

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Electronic component manufacturer

Customer's Needs and Problems

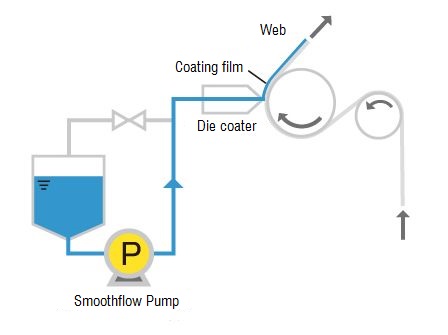

A die coater was used to coat the substrate with the electronic material.

A rotary metering pump was used to supply the liquid, which posed the following problems.

TACMINA's Solutions

We performed repeated tests using a Smoothflow Pump and the actual liquid at a TACMINA test facility.

The evaluations of the transfer accuracy and resistance to wear met the customer’s requirements, so they are now using this pump.

Flow Diagram

Product

- PLSS

- Max. discharge volume

- 0.14~2.5L/min

- Max. discharge pressure

- 0.5MPa

Ideal for the precision supply process for die coaters of various coating fluids and electrode materials

- Direct-Driven Type

- Precision

- Trace Amount Supply