Static Mixers

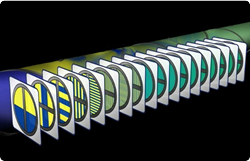

The static mixer is a unique standstill type with no actuator. Liquid that enters the mixer is sequentially mixed and stirred by elements.

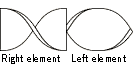

The Geometry of Static Mixer Elements

The element is a rectangular plate that is twisted 180 degrees, creating a right element and a left element, depending on the direction of the twist.

The basic length of each element is 1.5 times the diameter.

Mixing Principles of a Static Mixer

Static mixer efficiently mix through a process of division, conversion and inversion.

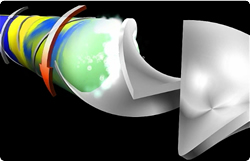

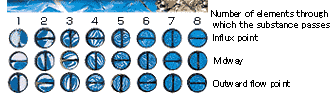

Division Process

Each time a liquid passes through an element, it is split in half.

Number of separations N=2n.ⁿN: Number of elements

Conversion Process

The liquid glides along the innner spiral walls of the element, moving from the center part of the cylinder to the walls, and from the walls to the center part, being sorted in the process.

Inversion Process

The liquids direction of rotation changes in each element, receiving rapid inversion of inertial force, which agitates the liquid.

Liquid-Liquid Mixing

ow viscosity substances with mutual solubility are mostly mixed through the inversion process. You can see that it is sufficiently mixed with relatively flew elements.

Liquid-Liquid Dispersion

Even with two low viscosity substances, without mutual solubility like water and oil, they are mostly dispersed during the conversion process.

You can see how the particles get smaller each time the fluid passes through the element.

Mixing of High Viscous Substances

Out of the three mixing principles, high viscosity material is mostly mixed during the division process and conversion process. You can see that with each element pass the ptripes increase and it is mixed.

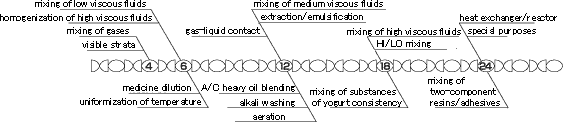

Number of Elements

Number of Elements Application Example

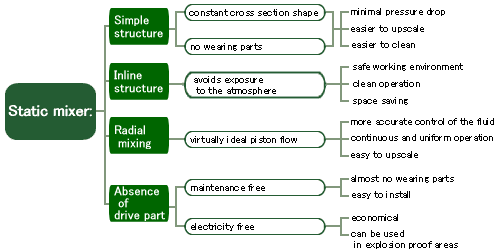

Features