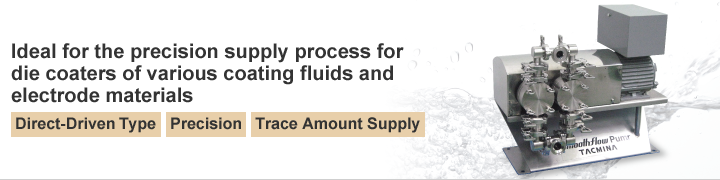

Smoothflow Pumps PLSS

Brochures

Features

The Fluid Is Transferred Steadily and Gently With the Diaphragm Type Pump.

Because it does not apply any local shearing force, no air is generated and the slurry is not damaged during the transfer.

Constant Flow Transfer Without Damaging the Fluid

Because there are no sliding parts, the fluid is not damaged and a uniform amount of fluid is constantly supplied.

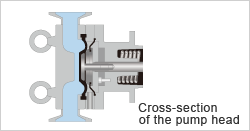

Easy to Disassemble and Designed for In-Process Cleaning

The pump head is easy to disassemble and the mirror-like surface finish makes it easy to clean.

Prevention of Horizontal Undulation by Refiner Effect

A refiner integrated into the main pump body suppresses even the slightest remaining pulsation to deliver a stable, constant flow.

No Risk of Foreign Matter Contamination

There is no chance of contamination due to foreign matter because the fluid has no contact with the open air and because there are no sliding parts. Additionally, the direct drive diaphragm pump has no risk of lubricating oil entering the system.

Compatible With Thin Film Coating Liquids of Various Properties

This diaphragm type pump can handle thin film coating liquids of any type ranging from heavy slurries to low viscosity or delicate fluids.

Smoothflow System

We offer a system that you can count on, with a design that maximizes the potential of Smoothflow technology and a configuration that puts safety and maintainability first.

Specifications

| Model | PLSS | |||||

|---|---|---|---|---|---|---|

| 01 | 05 | 09 | 1 | 2 | ||

| Max. discharge volume | (L/min) | 0.14 | 0.5 | 0.9 | 1.5 | 2.5 |

| (L/h) | 8.4 | 30 | 54 | 90 | 150 | |

| (US G/h) | 2.22 | 7.92 | 14.3 | 23.8 | 39.6 | |

| Max. discharge pressure | (MPa) | 0.5 | ||||

| (bar) | 5 | |||||

| (psi) | 72 | |||||