Use CasesEliminating the entry of foreign matter during the transferring of concentrated fruit juice

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Food manufacturer

Customer's Needs and Problems

Concentrated fruit juice (maximum viscosity: 20,000 mPa·s) is transferred from the raw liquid tank to the filling unit tank with a flow rate of 2 t/h.

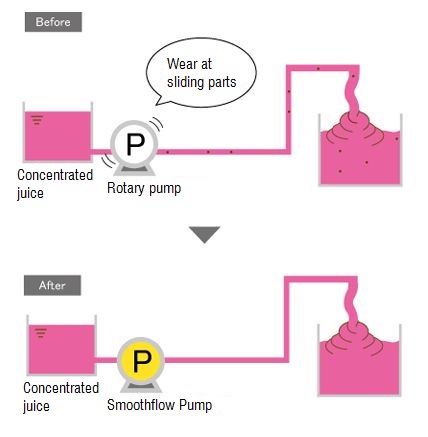

The existing rotary pump posed the following problems.

TACMINA's Solutions

The customer used a rental Smoothflow Pump to check the risk of the entry of foreign matter and to evaluate the transfer accuracy of high-viscosity liquid and the maintainability of the pump.

Thanks to the good results of their investigation, the customer decided to switch to a Smoothflow Pump.

Flow Diagram

Product

- APLS

- Max. discharge volume

- 1~45L/min

- Max. discharge pressure

- 0.5MPa

Ideal for transferring food, cosmetics and materials that are prone to deterioration caused by handling, such as concentrated juice, food additives, mayonnaise, and lotions.

- Direct-Driven Type

- Medium Capacity

- Sanitary