Use CasesImproving the coating quality of a die coater, long-term maintenance of initial performance

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Electronic material manufacturer

Customer's Needs and Problems

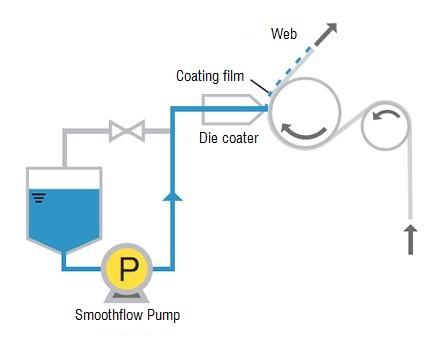

In the process in question, a die coater is used to apply to sheets the anode materials for lithium-ion batteries.

A rotary volumetric pump was used to supply the liquid, which posed the following problems.

TACMINA's Solutions

Considering the fact that a pump’s performance decreases due to wear in its sliding parts caused by the particles contained in the transfer liquid, the customer selected a Smoothflow Pump, which has no sliding parts.

We performed tests using the actual liquid at a TACMINA test facility, finding that our pump met the customer’s requirements for maintaining the initial performance and stability for a long period of time, which led to the customer using our pump.

Flow Diagram

Product

- TPL

- Max. discharge volume

- 0.1~30L/min

- Max. discharge pressure

- 15MPa

Ideal for process lines that require rigid control, such as optical film, IT, and high-purity pharmaceutical process lines

- Hydraulic

- High-Precision

- Ultra High-Pressure

- Trace Amount Supply