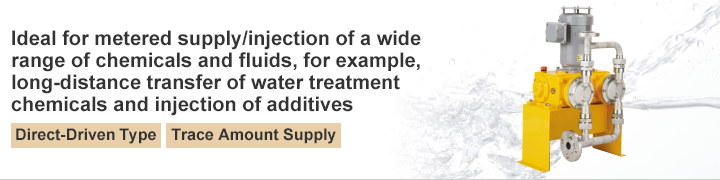

Smoothflow Pumps PL (Direct-Driven Type)

Brochures

Features

No Foreign Matter Contamination

Since the pump has no rotating or sliding parts, where foreign matter is normally generated, the risk of contamination is greatly reduced. This pump can be used with confidence in processes that require strict quality control, such as food, pharmaceutical, and electrical machinery manufacturing as well as many other critical applications.

No Reduction of the Flow Rate Even With Pressure Fluctuation.

Integrated backflow prevention means that the flow rate will not be reduced even when the pressure fluctuates. This is ideal for applications that require highly-accurate volume delivery such as mixing and coating pharmaceuticals and those that require accurate mixing ratios.

No Fluid Leakage

No mechanical seal to wear means no risk of leakage.

This is suitable for transferring toxic chemicals that are dangerous if leaked or fluid that is prone to evaporate.

No Break Down When Dry-Running

Thanks to its seal less design the pump does not require the fluid to lubricate the mechanism therefore even if the pump is run dry, it does not affect the drive components. There is no risk of pump break down even when dry-running occurs.

No Deterioration of Fluids

Unlike other products, Smoothflow Pumps never stir or agitates the fluid and they do not apply shear force. There is no risk of fluid deterioration or chemistry change caused by shearing, abrasion, pressure, or temperature change.

Designed for Optimal Slurry Transfer

As the Smoothflow Pump gently pushes the fluid, the wetted parts are not damaged by even the most aggressive slurries such as diatomaceous earth.

Enables Process Improvement

Provides a complete solution for optimization (time), yield improvement (product), and labor saving (people), all of which are identified as production process challenges. Product quality is further enhanced by eliminating the exposure of the fluid to open air and fluctuations in the injection amount.

Easy Maintenance

There is no need for an accumulator, expansion tank or any other device typically used for removing injection amount fluctuation.

As the wetted portion is small, the overall maintenance such as disassembly and cleaning can be performed very quickly and easily.

No Need for Dampener or Accumulator

Accumulators and other devices used generally reduce fluctuation have a slow response and, therefore, pressure control is indispensable. Smoothflow Pumps are quick to respond and there is no need for cumbersome pressure control and the associated maintenance for these devices..

Great Reduction in Potential Cause of Problems

A major source of problems is the process of stirring and mixing in the tank. This can be eliminated, significantly reducing the chance of accidents and failures.

Cost and Space Saving With Simpler Piping

Compared to conventional pumps that introduce pulsation, pulseless Smoothflow Pumps enable smaller diameter piping to be used on the discharge side. This reduces cost and the loss of transferred chemicals.

Excellent Responsiveness

In addition to pulseless operation, Smoothflow Pumps offer an instant response to flow rate change. Unlike the pulsation dampening achieved by a conventional air chamber, Smoothflow Pumps discharge immediately upon starting the operation and no liquid escapes when the operation is stopped, allowing for precise adjustment of supply volumes and mixing ratios.

Smoothflow System

We offer a system that you can count on, with a design that maximizes the potential of Smoothflow technology and a configuration that puts safety and maintainability first.