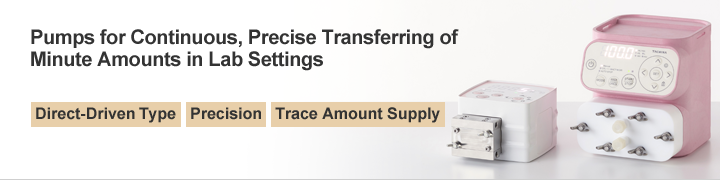

Smoothflow Pumps Q

Brochures

Features

Pumping performance and reliability that exceeds conventional laboratory pump expectations

Q Pumping Video

[0:34]

Excellent quantitative performance and responsiveness

The Q series pumps provide impressive quantitative performance with repeatability within ±1% (F.S.)*1

Flow rates can be finely configured at units of 0.01 mL/min (1 μL/min for the Q-5).

In addition, the excellent responsiveness allows for quick enforcement of starting and stopping operations and flow rate change operations.

- *1 For milliliter Class.

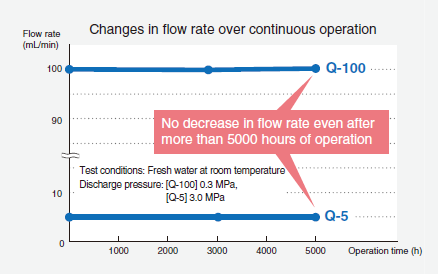

Ability to maintain pumping accuracy over long periods of time

Because there are no sliding parts, the load applied to the liquid-end section is small, preventing component wear and decreases in flow rate even with long-term use.

In other words, the service life of components is longer and running costs are low.

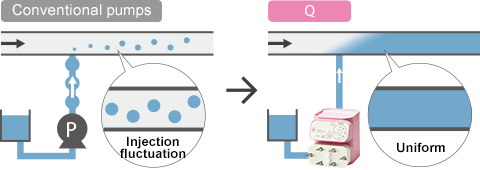

Continuous, constant flow with no pulsation

TACMINA's proprietary pumping mechanism (patented) enables pulsation-free continuous, constant flow even with diaphragm pumps.

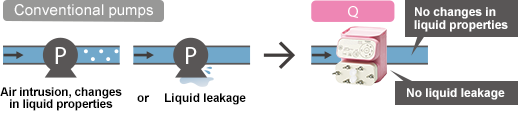

No liquid leakage or changes in properties

Because no sliding portions are used, localized pressure does not change, liquid is not altered by frictional heat, and solidification is prevented.

The completely sealed structure eliminates the need to worry about liquid leakage or contact with outside air.

Water-reactive substances*1 and other delicate liquids that may be altered if exposed to air can also be conveyed with no changes to the liquid properties.

- *1 Conditions apply. For details, contact TACMINA.

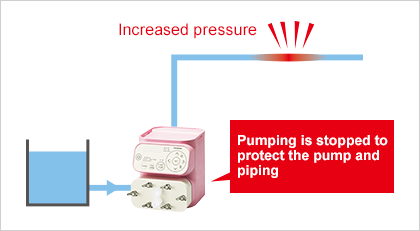

Not damaged by abnormal pressure or dry running

A built-in safety mechanism stops pumping if excessive pressure occurs. TACMINA's pumps ensure safe operation with no additional required components such as pressure sensors.

The absence of sliding parts means there's no need to worry about galling, seizing, wear, or damage even with dry running.

Simple transition to more powerful models

Utilizing the same pumping method, TACMINA Smoothflow Pumps are capable of high-capacity, high-pressure, high-accuracy pumping with support for slurries and the like.

Using pumps with the same pumping method in research and development as well as actual production lines allows for quicker time to commercialization.

Simple, user-oriented design

Flow rate change operation

[0:11]

Easy configuration of flow rate settings and calibration

Users can change the flow rate just by entering the desired rate.

Pump calibration can also be performed just by measuring and inputting the actual discharge rate. This allows for easy and accurate flow control.

Simple disassembly and assembly

The liquid-end section can be disassembled just by removing the wing bolts.

Because assembly can be performed without hesitation even for the first time, anyone can assemble the pump and maintain original performability.

Simple liquid switching

With a spare pump head set, liquid can be switched quickly just by replacing the pump head.

Users can also use pump heads for fluids requiring the use of different head material.

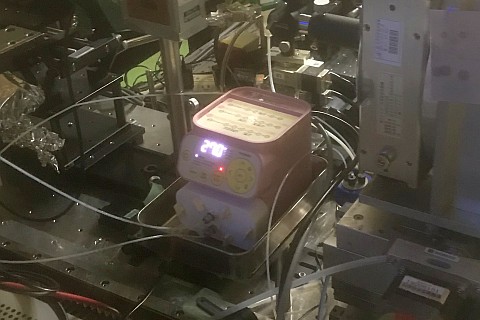

Easy to carry

The compact, lightweight construction allows the pumps to be placed anywhere and easily carried.

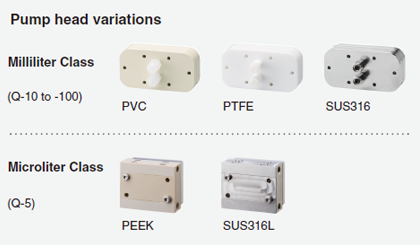

Capable of handling a wide variety of chemicals

Liquid-end materials with a high corrosion resistance are available to suit the properties of the liquid being used, including acids, alkalis, and organic solvents.

Also supports autoclave sterilization

A model whose entire liquid-end section can be sterilized with an autoclave is also available.

Various control functions

Auto-stop operation

[0:28]

Auto-stop operation (Compatible models: Q)

Operation times and discharge amounts can be set to stop pump operation automatically.

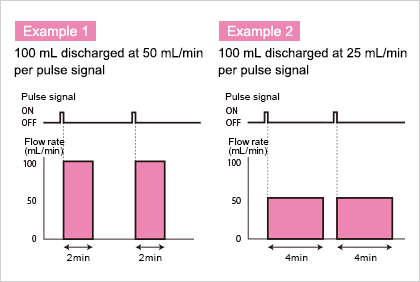

Operation relative to pulse input (Compatible models: QI)

Pumps can be operated automatically depending on a pulse signal input from an external device.

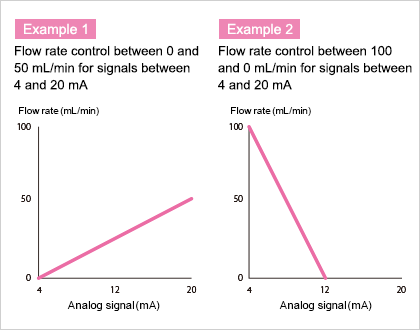

Operation relative to analog input (Compatible models: QI)

The flow rate can be changed automatically relative to an analog signal (4-12 mA DC) input from an external device.

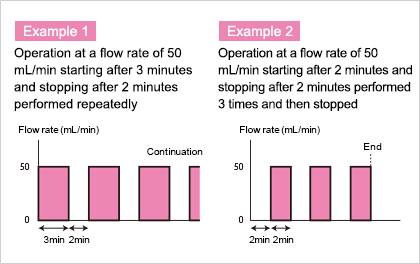

Interval operation (Compatible models: QT)

Pump operation can be turned ON and OFF at regular intervals repeatedly.

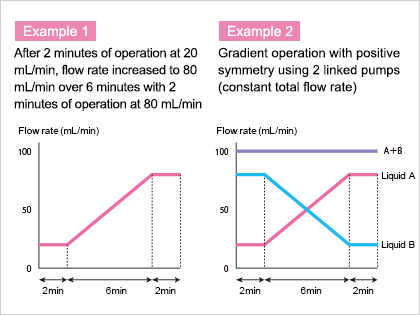

Gradient operation (Compatible model: QT)

Gradient operation

[0:53]

The flow rate of a pump can be gradually increased or decreased in proportion to how much operating time has passed.

Signal output function (Compatible model: QI, QT)

Signals can be output for use with external equipment.

| Unit pulse output | Pulse signal output after a specific amount is discharged |

|---|---|

| Alarm output | Signal output when an error occurs |

| Operation output | Signal output while the pump is in operation |

| Stop output | Pulse signal output when interval or gradient operation ends (QT only) |

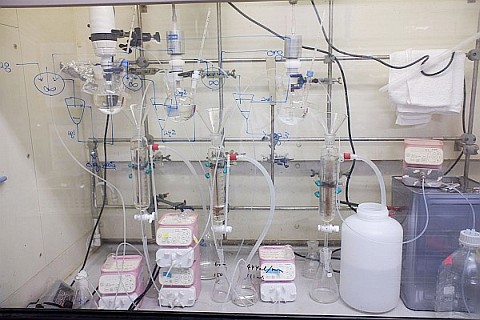

Smoothflow System

We offer a system that you can count on, with a design that maximizes the potential of Smoothflow technology and a configuration that puts safety and maintainability first.

Specifications

Milliliter Class

| Model | Q/QI/QT | |||||

|---|---|---|---|---|---|---|

| 100 | 60 | 30 | 10 | |||

| Maximum flow rate | (mL/min) | 100 | 60 | 30 | 10 | |

| (L/h) | 6 | 3.6 | 1.8 | 0.6 | ||

| (US G/h) | 1.58 | 0.95 | 0.47 | 0.15 | ||

| Flow rate control range | Variable from 0.1 mL/min to the maximum flow rate | |||||

| Maximum discharge pressure | (MPa) | 0.3 | 0.6 | 1 | 2 | |

| (bar) | 3 | 6 | 10 | 20 | ||

| (psi) | 43.5 | 87 | 145 | 290 | ||

Microliter Class

| Model | Q/QI | |||||

|---|---|---|---|---|---|---|

| 5 | ||||||

| Maximum flow rate | (μL/min) | 5000 | ||||

| (L/h) | 0.3 | |||||

| (US G/h) | 0.07 | |||||

| Flow rate control range | Variable from 5 μL/min to the maximum flow rate | |||||

| Maximum discharge pressure | (MPa) | 3 | ||||

| (bar) | 30 | |||||

| (psi) | 435 | |||||