Smoothflow Pumps Customized Models

Brochures

Pump Customization

TACMINA is no stranger to pump customizations. Smoothflow Pumps are individually manufactured and often incorporate specification and design changes according to customer requests. Some of the most common customizations are outlined below. Various other customizations are also available, so don’t hesitate to ask a representative for more information.

Typical Customizations

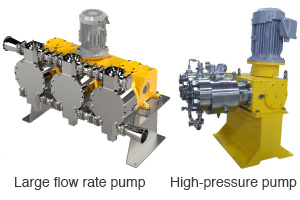

Discharge Volume & Pressure

The flow rates and pressures listed in product catalogs are merely examples of standard specifications. Sometimes customers want a pump with a higher flow rate. Other times they are looking for higher pressures. Whatever the case, TACMINA strives to design and manufacture pumps that meet any special request, so feel free to contact us for more information.

Support for Slurries and High-Viscosity Liquids

For slurry liquid transferring, TACMINA offers customizations for the material and shape of liquid end parts following advance verification of such factors as concentration of solids, particle size, specific gravity, and hardness, thereby preventing wear, clogging, and other problems from occurring.

For high-viscosity liquids, TACMINA’s use of specialty parts means pumps can be used even for liquids with greater viscosities than those listed in the catalog specifications.

TACMINA also offers analysis services for customer liquids in addition to testing device rental and actual liquid testing to confirm transferability.

Liquid End Materials

Depending on the liquid being transferred, such as with highly corrosive liquids or abrasive slurries, standard pump materials may result in a shortened service life of the pump. TACMINA manufactures pumps from a variety of materials, in addition to those listed in product catalogs. In addition, durability and cost performance are factored into any proposed material.

| Common materials | Special materials | |

|---|---|---|

| Metals |

|

|

| Resins |

|

|

- ※

The materials that can be selected for standard products vary by model.

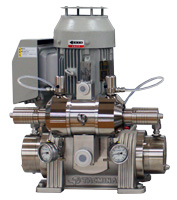

Sanitary Specifications

Sanitary specifications are easy to clean, making them the recommended choice for production lines for foods and pharmaceuticals or for applications where frequent cleaning and liquid replacement are required.

- Surface treatment on liquid end parts (buffing, electropolishing, mirror finishing)

- Ferrule joints for easy removal to facilitate disassembly and cleaning

- Support for clean-in-place (CIP), sterilize-in-place (SIP), etc.

Wide Range of Control

Changing the flow rate on a Smoothflow Pump is done by using an inverter to control the number of rotations of the motor. For standard specifications, control is generally in the range of 1:10. Using a dedicated motor and inverter enables a wider range of control at up to 1:100.

- ※

*Q Series pumps are capable of control at 1:1000 (0.1 to 100 mL/min) as standard.

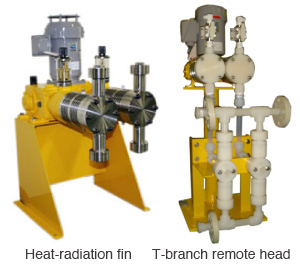

High-Temperature Usability

Pump head customizations make it possible to transfer liquids even in excess of 100°C without damaging the pump.

- Heat-radiation fin specifications

- Remote head specifications

- T-branch remote head specifications, etc.

Smoothflow Pumps can be equipped with a heater, chiller, or heat-insulating jacket to keep liquid temperatures constant.

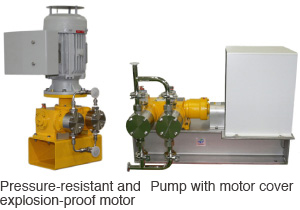

Explosion Proofing, Custom Enclosure Rating, etc.

TACMINA offers replacement options for the motor, inverter, and other components in order to design and manufacturer pumps that meet a customer’s specific standard needs.

- Explosion proofing (explosion-proof, with increased safety; pressure-resistant and explosion-proof)

- Insulation (heat resistance)

- Varying voltage support

- IP enclosure rating, etc.

Housing Surface Treatment

Electroless nickel plated pump

Electroless nickel plated pump

Electroless nickel plating is available if paint on the pump housing will pose a problem, such as when using solvents.

Special requests for pumps are also accepted, including requests for paint in a color specified by the customer, or salt-resistant paint.

Unit Production

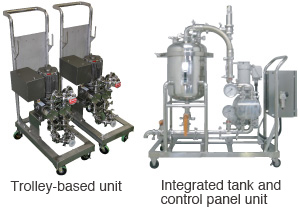

TACMINA provides unit pumps to suit the application, including easy-to-maneuver trolley-based units and liquid transfer pumps complete with a tank, control panel, or other components.

- Related information

- Smoothflow System

Application-Specific Pumps

TACMINA is always open to coordinating with customers for joint development of specialized pumps designed to suit individual applications.

This makes it possible not only to solve problems that could not be solved with existing products but also to improve the overall process.

- Bead mill pumps

- Precision coating pumps

- Microreactor pumps, etc.