Use CasesStabilizing disperser operation by preventing bead biting

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Battery manufacturer

Customer's Needs and Problems

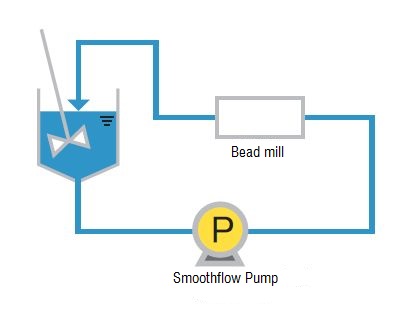

A pump is used to supply anode material (carbon slurry) to a bead mill, where the material is dispersed.

Conventionally, a rotary volumetric pump was used, which posed the following problems.

TACMINA's Solutions

We suggested that the customer use one of our Smoothflow Pumps, which have a successful history of transferring battery material slurry, and they agreed to this proposal.

Flow Diagram

Product

- APLS

- Max. discharge volume

- 1~45L/min

- Max. discharge pressure

- 0.5MPa

Ideal for transferring food, cosmetics and materials that are prone to deterioration caused by handling, such as concentrated juice, food additives, mayonnaise, and lotions.

- Direct-Driven Type

- Medium Capacity

- Sanitary

- Customized Models

Flexible ideal solutions that meet the needs of specialized manufacturers.