Smoothflow Case Studies

Do you have problems or are unhappy with the pump you currently use - leakage, contamination, fluid deterioration, or lack of ease in maintenance?

Smoothflow is the answer!

Smoothflow Pumps are accurate, durable and easy to maintain. They are field-proven to improve product quality.

Problems Solved With Smoothflow Pumps

I would like to improve the coating liquid supply.

I would like to improve the coating liquid supply.

Smoothflow Pumps offer a complete solution to various problems associated with the transfer of coating fluids.

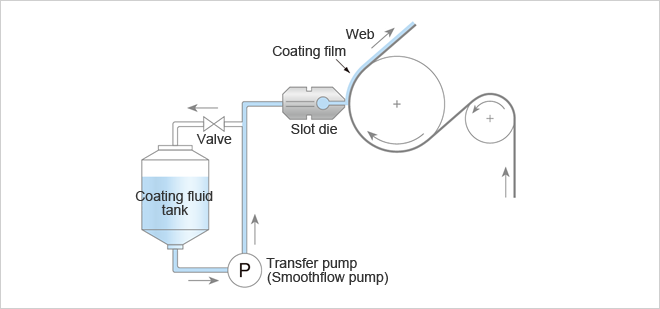

For example, when transferring coating fluids to a die coater…

Because of the pulsation, the flow rate is not constant, causing the coating thickness to be uneven. Smoothflow Pumps deliver constant and continuous flow, resulting in a consistent uniform coating thickness.

Friction caused by the internal parts of conventional pumps often cause shearing stress, and sometimes cause cavitation or bubbles to form. Smoothflow diaphragm pumps move the fluid gently without applying any shearing force.

The flow rate may fluctuate due to backflow when pumping low viscosity fluids with a conventional pump. With a Smoothflow Pump, backflow is prevented by the check valve and the flow rate is always stable and constant.

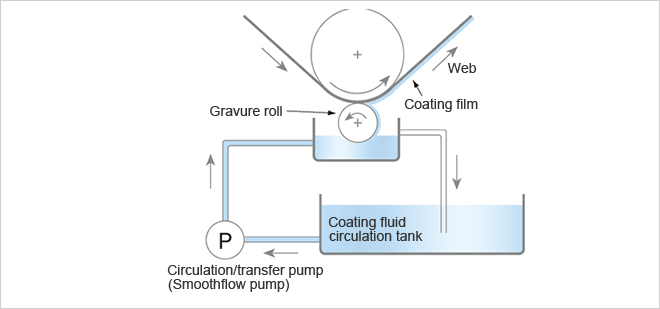

When transferring coating fluids to a gravure coater or a dip coater…

Smoothflow Pumps are easy to clean and maintain.

Smoothflow Pumps are pulse-free. The fluid level always remains constant and no wave occurs on the fluid surface in the pan. The fluid is transferred gently without shear, causing no deterioration to the fluid.