Smoothflow Case Studies

Do you have problems or are unhappy with the pump you currently use - leakage, contamination, fluid deterioration, or lack of ease in maintenance?

Smoothflow is the answer!

Smoothflow Pumps are accurate, durable and easy to maintain. They are field-proven to improve product quality.

Problems Solved With Smoothflow Pumps

I would like to stabilize my long-distance transfer.

Problems and Concerns

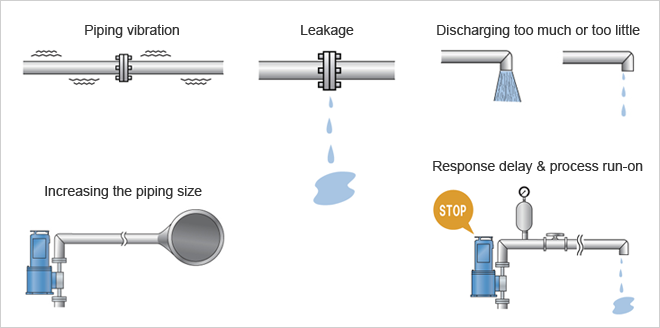

We are using a diaphragm pump, but because of the long piping, we are suffering from vibration and leakage.

It is costly to enlarge the piping as a countermeasure, and we don't want to waste the residual fluid in the piping, either.

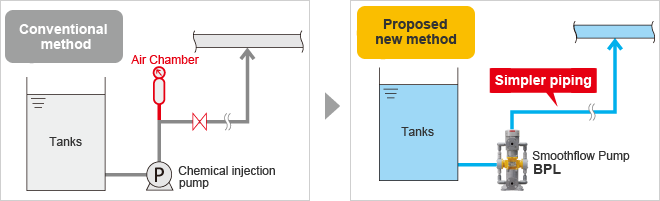

Using an air chamber makes the pump slow in response, and maintenance becomes cumbersome.

Are there any good solutions to these issues?

Solution

Piping vibration and leakage is caused by the "pulsation" created by conventional diaphragm pumps.

Smoothflow Pumps are pulse-free - pressure loss and inertia resistance are low so you can use thinner wall piping. You also will not need an air chamber.

Injection over long distance piping.

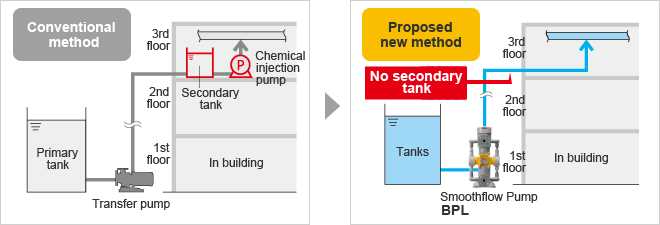

High-pump-head transfer from the primary tank