Static Mixers

The static mixer is a unique standstill type with no actuator. Liquid that enters the mixer is sequentially mixed and stirred by elements.

Mixing

Our technology ensures an ideal mixing of liquids.

The mixing process includes dilution, neutralization, division, extraction and so on.

The static mixer, through the three mixing principles of division, conversion and inversion, can be conformed to the various mixing process.

Compared to a conventinal Batch System, it is superior in reproducibility, precision and consistent mixing. Also, the static mixer is inexpensive to maintain, energy efficient and spave efficient. We carry a wide variety of models to ment all type of needs.

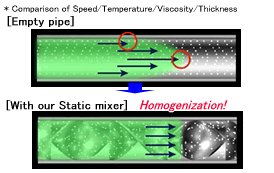

Homogenization

Our technology ensures a precise homogenization of fluids.

Inside the pipe the liquid flow increases, so that a lack of uniformity may easily occur. Because of this, problems such as unevenness in temperature or viscosity may lead to a lack of uniformity in products.

The mixing effect of our static mixer is due to the radial shape of the interior, which renders the mixed fluids homogeneous. Moreover, the simple form of our machine ensures a uniform mixing so that almost no deposits of fluid are left out.

Another improvement can be noticed in the case of resin cast modeling, where the homogenization of molten materials, as well as their temperature and concentration are detected with a sensor which ensures the accuracy of measurements.

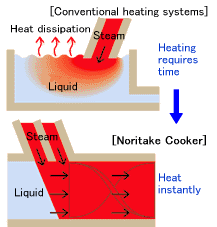

Direct Heating

Our product ensures speedy heating, which prevents unevenness in heating.

Steam is directly injected into the liquid and through condensation the high quantity of heat contained by the steam (cca.650 kcal/kg) is transmitted to the liquid. The static mixer further minimizes the steam, and the condensation is instant. As a result, the time necessary for heating is increasingly shortened.

Moreover, the mixing performed with our static mixer ensures a uniform heating. This is effective in the process of heating of salting out necessary for the production of ABS plastic, heating of PVC slurry and pudding sterilization.

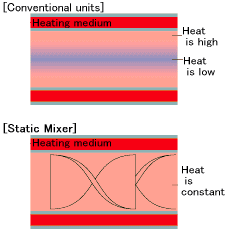

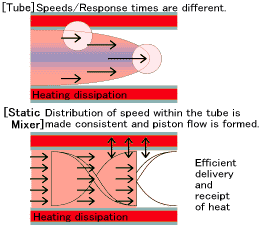

Heat Exchange

With our product, the efficiency of heat exchange has dramatically increased.

The radial mixing operation performed by the static mixer is also efficient due to a decrease in the resistance of the membrane bordering the tube walls, which greatly improves the ratio of heat exchange (3 to 5 times). The result is visible in the case of high viscous fluids.

Moreover, the static mixer performs a radial mixing operation in which the fluid is constantly shifting from the pipe wall to the center. This shortens the time of fluid exposure to the temperature of the hot medium, preventing the deterioration of the product.

The heat exchange function can be effectively used in a variety of operations and domains, such as the heating of silicone oil or in the cooling process of food production.

Reaction

We proudly present the excellent performances of our inline type successive reactor.

The piston flow motion and the reaction heat created by our static mixer ensures a highly efficient exchange of heat. This function can be employed for reactions, such as successive polymerization of polymers, maleinization, as well as other reactive processes used in chemical industry.

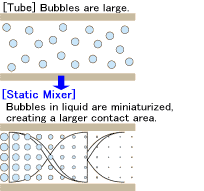

Gas Absorption

Our product ensures a rapid dissolving of gases.

The process of dissolving a gas into a liquid necessitates low temperatures and high pressure. Moreover, a large contact surface is mandatory.

Inside our static mixer the gas bubbles undergo a process of minimization, and therefore, the contact surface is increased. As a result, the efficiency of dissolving the gas rapidly increases.

This function can be successfully used in the process of aeration, absorption of carbonic gas in the production of beer, or in the absorption of ammonia gas in water in the production of ammonia water.