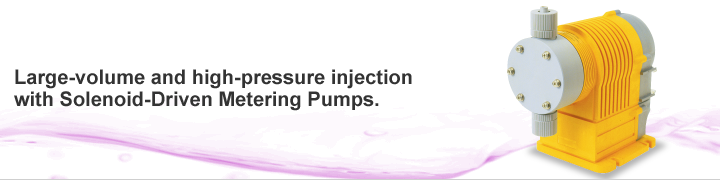

Solenoid-Driven Metering Pumps PZiG

Brochures

Features

Large-Volume Injection

A product lineup of four models up to 300 to 1000mL/min.

Can Be Used With High Viscosity Liquids

Also use for polymer coagulant injections.

- * Transfer of high viscosity liquids may not reach the prescribed maximum discharge volume. To transfer high viscosity liquids, please contact us for application support.

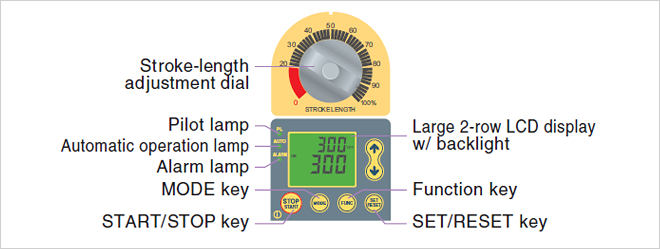

Enter Injection Amounts Directly and Select From Three Patterns of Injection Amount Settings

Set by stroke speed

- Setting range

- 1 to 300 strokes/min (can be set to 1 stroke/min)

Set by discharge amount

- Setting range

- From 0.1 (maximum discharge amount for selected model)/mL/min (can be set to 0.1mL/min)

Set by percent

- Setting range

- 1 to 100% (for a maximum stroke count (300 strokes/min) of 100%, can be set per 1%)

Large Two-Row Display Panel With Backlight and Simple Operation Keys

Free Power Supply

100 to 240 VAC (±10%) operation means you do not need to worry about voltage fluctuations at the site. This pump can be used at a variety of locations and for a variety of purposes.

Water-Resistant, Dustproof Construction

- IEC standard

- IP65 equivalent

An Array of Wetted Part Materials to Handle a Wide Variety of Chemicals and Uses

- VTCE/VTCF

- Material

- Polyvinyl chloride (PVC)

- Use example

- Transfer/injection of general medication

- FTCT

- Material

- Fluorocarbon resin polyvinylidene fluoride (PVDF)

- Use example

- Transfer/injection of strong acids, nitrating acids and other special medications

- VTCF (High Viscosity Type)

- Material

- Polyvinyl chloride (PVC)

- Use example

- Transfer/injection of high viscosity medication

- * Stainless steel types (SS304/316) are also available by special order.

Simple Correction to Actual Discharge Amount

Simple correction function to automatically discharge 300 strokes of chemicals. Just enter the discharge amount into this device to use the actual flow amount for an easy and accurate correction.

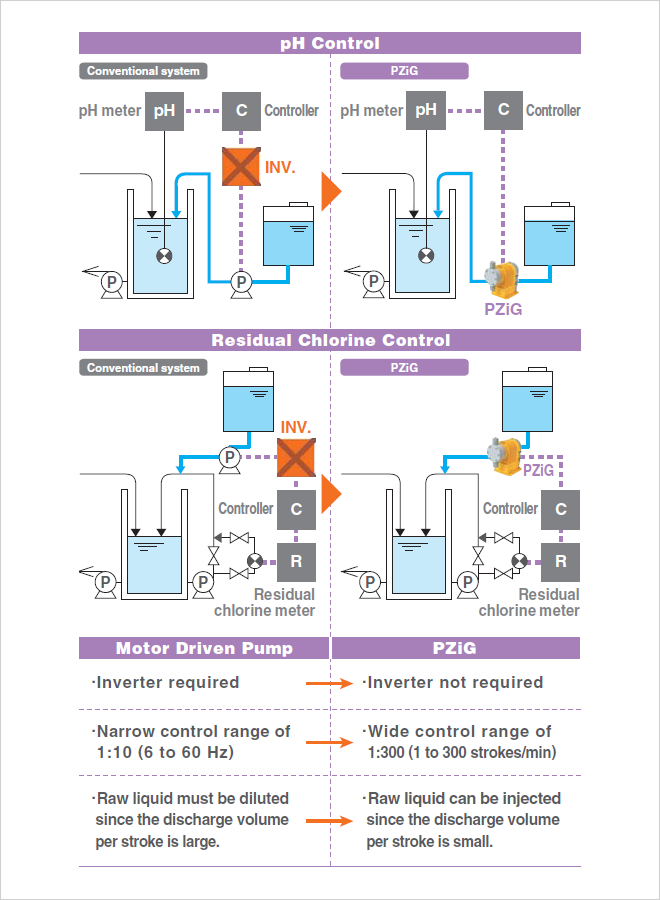

Analog Input Proportional Control

Injection amount (stroke speed: 0 to 300 strokes/min) can be set based on analog input signals (4 to 20 mA) from an external source to control pH, residual chlorine and a wide variety of other uses.

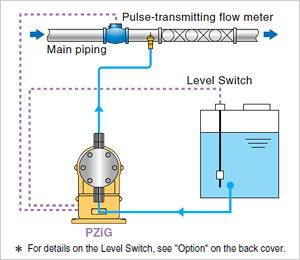

Pulse Input Proportional Control and Stop Input Control From Outside

Not only can the pump ON/OFF be controlled via an external input, injection amount (1/9999 to 9999 strokes/pulse) can also be set based on pulse input signals. Interlocking with a pulse-emitting flow meter or level measurement enables simple execution of a variety of simple automatic controls.

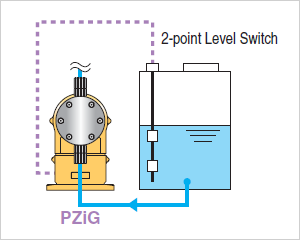

Two-Point Control of Level Measurements

Control alarm display and generation, pump stop and other controls based on the amount of chemicals remaining in the tank.

Count Driving (Batch Injection Control) and Interval Driving (Timer Injection Control)

- Count settings

1~9999strokes(×1,×10,×100,×1000)

- Interval settings

- ON time

- 1~9999min

- OFF time

- 1~9999min

Specifications

For Injection of Generic Chemicals, For Injection of High Viscosity Medicines

| Model | PZiG | ||||

|---|---|---|---|---|---|

| 300 | 500 | 700 | 1000 | ||

| Max. discharge volume | (mL/min) | 340 | 530 | 760 | 1000 |

| Max. discharge pressure | (MPa) | 1.0 | 0.7 | 0.4 | 0.3 |