Solenoid-Driven Metering Pumps DCLPW・CLPW

Brochures

Product Introduction Video

Features

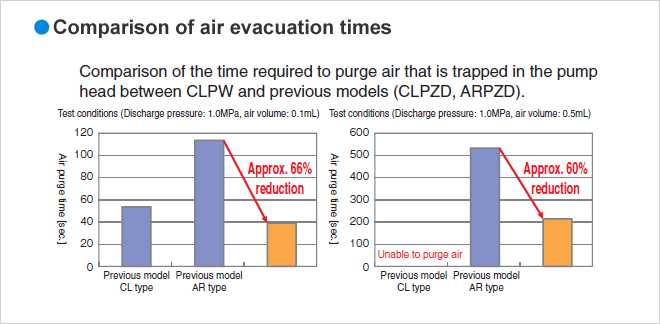

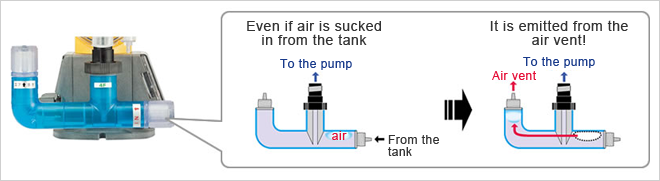

Automatic Air Evacuation Mechanism to Ensure Intake Air Elimination

Automatic air evacuation mechanism ensures intake air is eliminated.

Air block construction video

[0:23]

Air-Block Mechanism to Prevent Air Mixing in the Pump Head (DCLPW only)

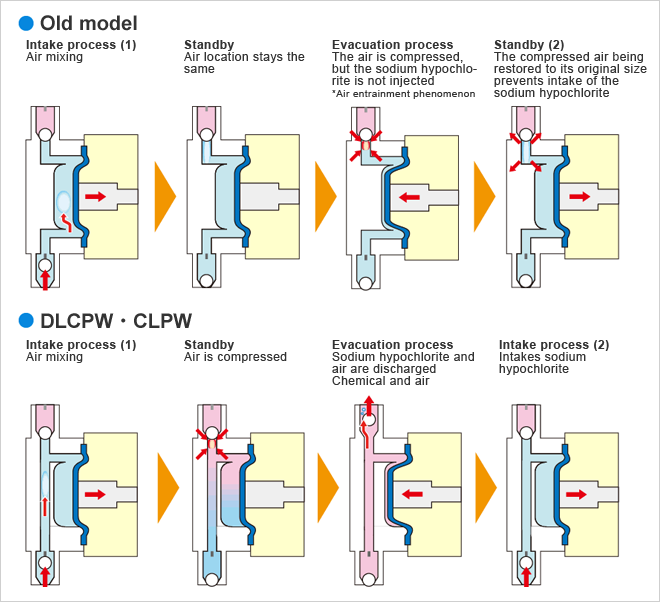

The most common cause of sodium hypochlorite injection defects is "air-mixing". This occurs when air becomes trapped inside the pump head.

The DCLPW is mounted with an air-block mechanism to prevent air mixing. Even if 15 cc of air is sent in one burst, there is absolutely no mixing inside the pump head.

To prevent injector defects, obstructing air mixing is critical.

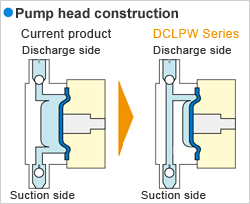

Pump Head Construction That Controls Air Retention

Flow routes inside the pump head are made as narrow as possible to minimize dead space, which not only reduces the amount of mixed air and air retained, but makes air easier to evacuate air by increasing the compression ratio.

Transparent Acrylic Head Allows View of the Pump Head Interior at a Glance

Use of a transparent acrylic head allows view of pump operation, air mixing and retention at a glance.

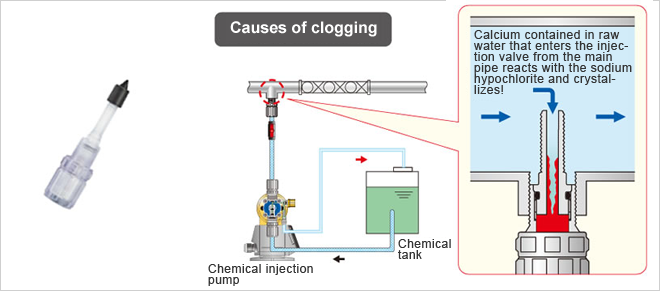

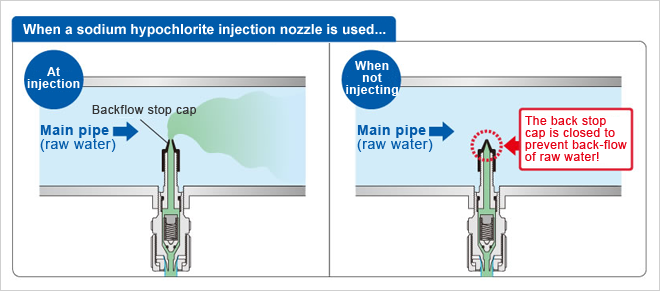

Injection Nozzle for Sodium Hypochlorite to Prevent Clogging of the Injection Point

The injection nozzle was developed exclusively for sodium hypochlorite to prevent crystallization and clogging due to back-flow or reactions with raw water.

Other Pumps for Sodium Hypochlorite

- CLPZ

- Max. discharge volume

- 100mL/min

- Max. discharge pressure

- 1.0MPa

- ARPZ

- Max. discharge volume

- 93mL/min

- Max. discharge pressure

- 1.0MPa

Specifications

For Injection of Sodium Hypochlorite (NaClO)

| Model | DCLPW・DCLPWM・DCLPWT | CLPW・CLPWM・CLPWT | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30R | 60R | 100R | 30 | 60 | 100 | 30R | 60R | 100R | 30 | 60 | 100 | ||

| Max. discharge volume | (mL/min) | 30 | 60 | 90 | 30 | 60 | 90 | 30 | 60 | 90 | 30 | 60 | 90 |

| Max. discharge pressure | (MPa) | 0.7 | 1.0 | 0.7 | 0.7 | 1.0 | 0.7 | ||||||