Smoothflow Case Studies

Do you have problems or are unhappy with the pump you currently use - leakage, contamination, fluid deterioration, or lack of ease in maintenance?

Smoothflow is the answer!

Smoothflow Pumps are accurate, durable and easy to maintain. They are field-proven to improve product quality.

Problems Solved With Smoothflow Pumps

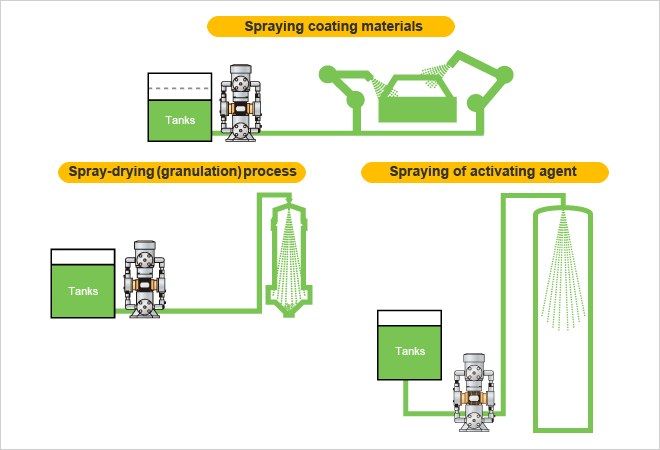

I would like to improve my spraying process precision.

Problems and Concerns

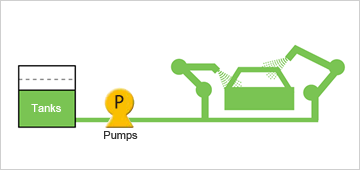

When spraying paint, the viscosity of the paint varies based on the amount of paint remaining in the tank, spraying position, and the temperature, causing the flow rate to change, affecting the coating thickness.

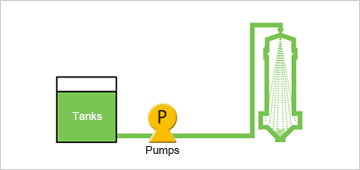

In the spray-drying (granulation) process, we cannot obtain uniform granularity because the fluid flow rate is not stable.

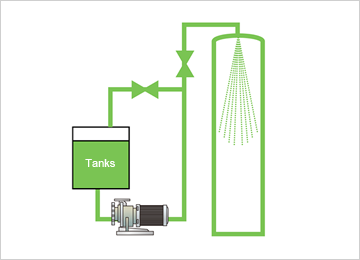

We are using a large-capacity magnet pump through a bypass to transfer small quantities of the fluid, but we cannot obtain stable flow because of large backflow.

Solution

Smoothflow Pumps prevent backflow using a check valve. It is capable of spraying a predetermined amount of paint at a constant pressure, providing perfectly uniform coating.

Moreover, Smoothflow Pumps do not have any sliding parts, thus it can handle slurry very well, with excellent resistance to abrasion. Smoothflow Pumps are ideal for high-pressure, low-volume transfers because of its simple piping.