Basics|Precision pumping technology 9-4. Gas Lock Caused by Rapid Liquid Temperature Change

The previous sections discussed conditions and phenomena on the premise that the liquid temperature is constant.

However, although rare, the in-tank temperature and the temperature around the pump can differ significantly in certain real-life applications. Care must be used for processes where cold liquid is transferred to a warm place. Temperature differences in the system can also adversely affect the pump.

We went over many times during this course that more gas dissolves in liquid at higher pressures. However, there is another important element with regard to gas dissolving in liquid--more gas dissolves into liquid at lower temperatures.

Conversely, this means that gas diffuses out of the liquid as bubbles at higher temperatures.

As an example, let's consider transferring cold water in winter.

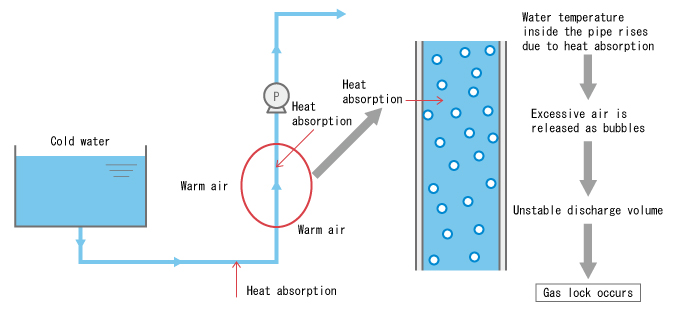

A certain amount of air is dissolved in the cold water in the tank. This water passes through the suction-side hose and flows into the pump head--this is where a problem arises.

Heat transfers from the higher temperature side to the lower temperature side. This is an invariant principle of thermodynamics.

According to this principle, heat transfers from the warm air around the pump to the cold water in the hose, raising the temperature of the water inside the hose.

As a result, dissolved air diffuses out of the liquid as bubbles. Further, the negative pressure generated inside the pump head facilitates the production of bubbles. Apparently, this constitutes a cause for gas lock and cavitation, so measures must be taken against it.

The temperature increase in the cold water tank is significantly delayed compared to the water temperature increase in the hose due to the former having higher water volume (larger thermal capacity) and smaller area of contact with outside air compared to the latter.

Generally in such cases, insulators are used to cover the tank, pump, and piping in order to minimize the difference in the water temperatures. You may have seen insulation materials around many outdoor installations, but these are not necessarily only for the purpose of preventing freezing.

As we have learned here, even when the temperature does not drop to the freezing point of the liquid, insulation may still be required to retain metering performance.

Gas locks are also discussed in the Topic "What is Gas Lock?" A video on TACMINA's anti-gas lock pump, designed specifically for the sodium hypochlorite process, is also available for your viewing ("Actual video of automatic air release mechanism").

TACMINA's DCLPW Series, dedicated to sodium hypochlorite injection, offers a perfect solution to injection problems with its double block mechanism that prevents gas locks.

More...

Articles List for Precision pumping technology

- 9-4. Gas Lock Caused by Rapid Liquid Temperature Change

- 9-3. Solutions for Gas Lock: Removing the Bubbles Inside the Pump Head

- 9-2. Solution for Gas Lock: Increasing the Pressure Inside the Pump Head So That It Exceeds the Discharge Pressure