Basics|Precision pumping technology 9-2. Solution for Gas Lock: Increasing the Pressure Inside the Pump Head So That It Exceeds the Discharge Pressure

As can be identified from the causes of gas locks, there are broadly two ways to remove gas locks:

- (1)

Increase the pressure inside the pump head so that it exceeds the discharge pressure.

- (2)

Remove the bubbles inside the pump head.

Now, let's look at each approach.

Increasing the Pressure Inside the Pump Head So That It Exceeds the Discharge Pressure

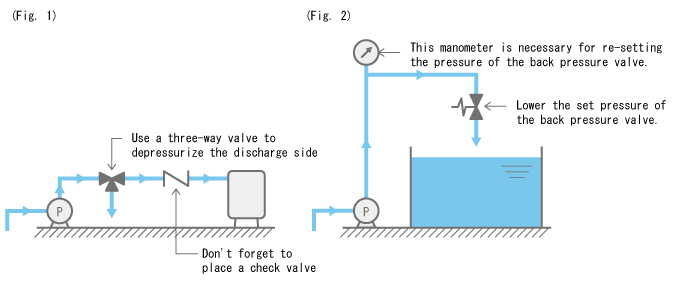

The easiest way to accomplish this is to depressurize the discharge side by opening the discharge-side valve to atmospheric pressure. If the pump is injecting liquid into a high-pressure tank, relieve the pressure using a three-way valve. (Between the three-way valve and the high-pressure tank, be sure to place a check valve in the direction necessary to stop backflow from the tank.) -- Fig. 1

If a back pressure valve is used, lower the set pressure. -- Fig. 2

Using this procedure, the pressure at the discharge side is mostly reduced to atmospheric pressure, resolving the gas lock.

If a system is using a flow rate adjustment dial to reduce the flow rate (using shorter strokes), you may be able to resolve the gas lock by re-adjusting the stroke length so that it is as long as possible, which increases the compression rate in the pump head.

(This method only works when the amount of gas is small.)

Gas locks are also discussed in the Topic "What is Gas Lock?" A video on TACMINA's anti-gas lock pump, designed specifically for the sodium hypochlorite process, is also available for your viewing ("Actual video of automatic air release mechanism").

TACMINA's DCLPW Series, dedicated to sodium hypochlorite injection, offers a perfect solution to injection problems with its double block mechanism that prevents gas locks.

More...

Articles List for Precision pumping technology

- 9-4. Gas Lock Caused by Rapid Liquid Temperature Change

- 9-3. Solutions for Gas Lock: Removing the Bubbles Inside the Pump Head

- 9-2. Solution for Gas Lock: Increasing the Pressure Inside the Pump Head So That It Exceeds the Discharge Pressure