Topics|Smoothflow pumps Smoothflow Pump Strengths per Rechargeable Battery Production Process

Smoothflow pumps play a role in a number of processes within rechargeable battery production. We offer better "Liquid Solutions" that exceed customer expectations with improved performance and assured safety.

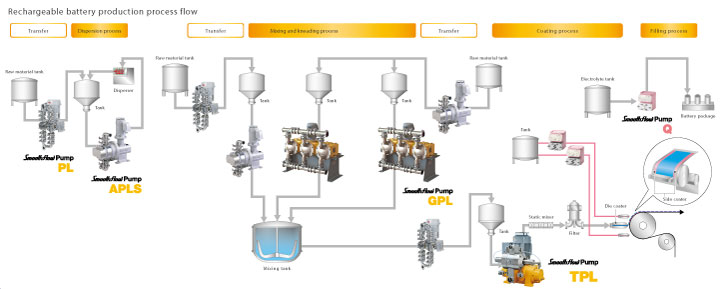

Rechargeable battery production process flow

Dispersion process, Mixing and kneading process, Coating process, Filling process, Smoothflow pumps play a role in a number of processes within rechargeable battery production.

Smoothflow Pump Strengths per Rechargeable Battery Production Process

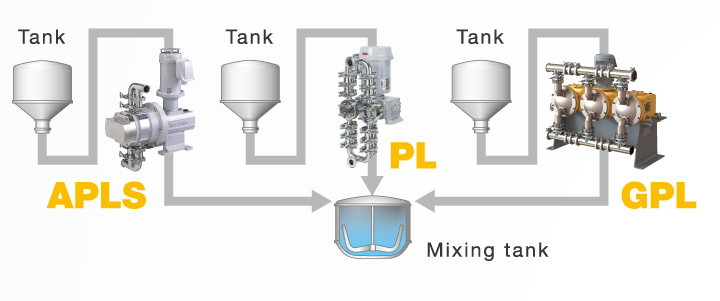

Mixing and kneading process Gentle transfer without wear or changes in liquid quality

- No pulsations allows for accurate mixing

- Able to safely transfer binder liquids and other easily gelled liquids without change in liquid quality

- Batch/continuous mixing and kneading possible from small to large flow rates

Transfer liquid examples:SBR, binder liquids, active materials (nickel mixtures), CNT slurry liquid with conductive material, NMP, PVDF, etc.

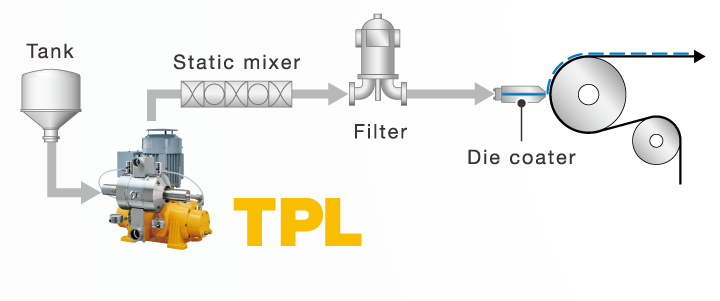

Coating process Improved coating quality, Very small volume transfer to side coater (insulator coating)

Coating process

- No effect from liquid viscosity fluctuations or pressure fluctuations caused by filters

- Maintains initial performance for a long period of time

- No particle aggregation or bubbling caused by the pump

- Static mixer helps prevent electrode material slurry sedimentation

Transfer liquid examples:Cathode/anode material coating solutions

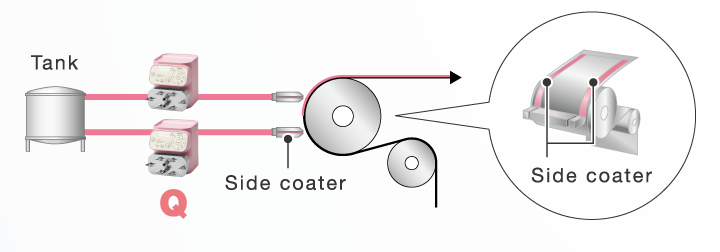

coater (insulator coating)

- Stably transfers both low-viscosity liquids and slurry liquids

- No liquid leakage due to wear

- Compact size (palm-sized)

Transfer liquid examples:Alumina slurry, PVDF, etc.

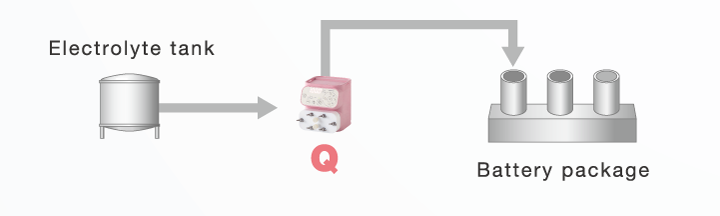

Filling process Continuous and precise liquid transfer of very small volumes

- Superior metering characteristics and responsiveness

- No crystallization caused by air entry

Transfer liquid examples:Electrolytes, etc.

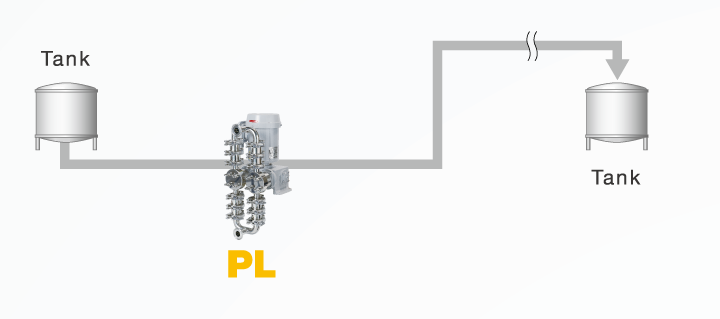

Transfer process Stable transfer without pulsation

- Sustains high transfer accuracy over long time periods

- No flow rate decrease due to wear

- Long-distance transfer possible even for high-viscosity liquids

Transfer liquid examples:Electrode slurry liquid, active materials, CNT slurry liquid with conductive material, NMP, PVDF, electrolytes, etc.

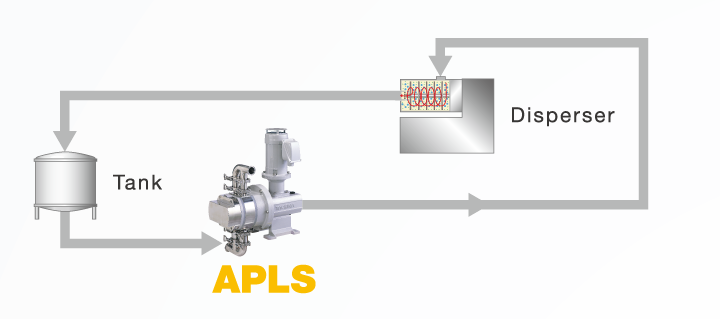

Dispersion process Improved grain size distribution

- No bead unevenness, delivers sharp grain size distribution

- No entry of foreign matter, and fibers in materials are not cut

- Simple structure means easy cleaning and excellent maintainability

Transfer liquid examples:CNT slurry liquid with conductive material and other mixtures

Contributes to consistent quality in rechargeable battery production

Taking rechargeable battery quality to an even higher level.

Highly stable liquid transfer/h3>

Delivers superior performance in processes that demand extreme precision. Achieves consistent film forming in the coating process.

No adverse effects from pressure/viscosity fluctuations

Delivers stable discharge performance even as pressure and viscosity change.

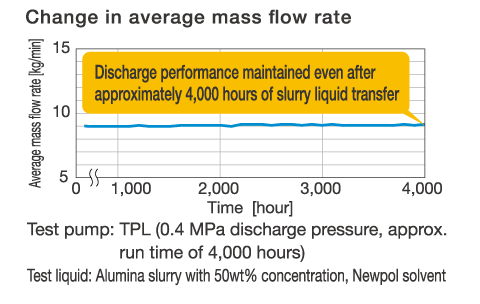

Long-term stability even with highly abrasive slurry liquids

The structure has excellent wear resistance, which means that even with highly abrasive slurry liquids, flow rate does not decrease due to pump parts wear or leakage.

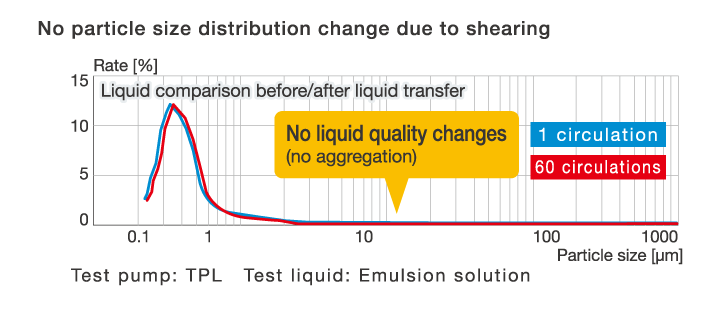

No liquid quality changes

流Because liquids are not stirred and excessive localized pressure is not applied, there is no risk of liquid quality changes due to shear, abrasion, or temperature. There is no slurry re-clumping or gelation, nor temperature increases in the liquid caused by the pump.

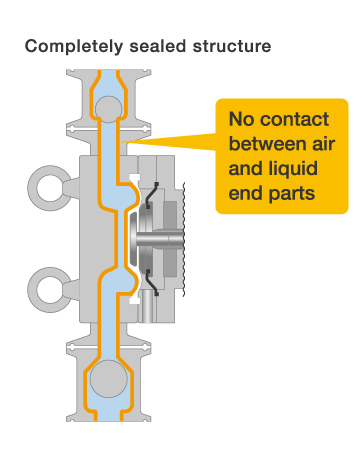

No bubbles

No shaft seals means that air is not drawn in from the outside. The liquid does not contact the air, meaning no dangerous gases are generated.

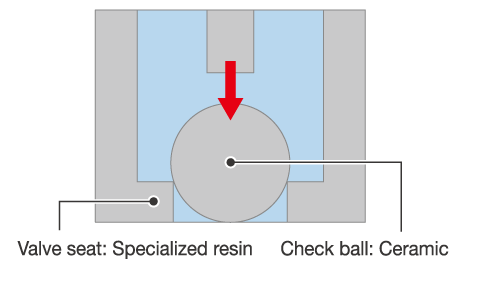

No worries about metal contamination

There are no sliding parts or shaft seals, so wear is avoided. The seal surface on which the check ball sits has a very small contact area and low contact frequency. Ceramic and resin are used for these parts. (PLB Series is standard specifications)

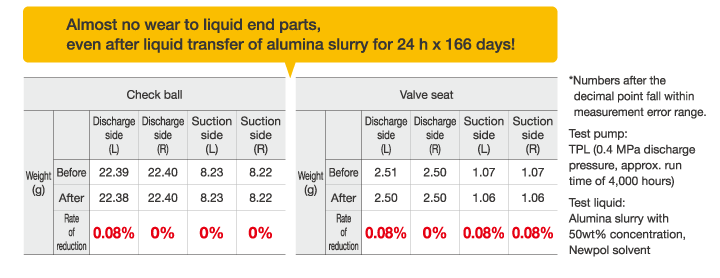

Resistant to slurry damage

The liquid end parts have no mesh parts, which means that pump parts experience almost no wear, even when transferring abrasive slurries. Contamination risks can be reduced.

Material Restrictions

Our Smoothflow pumps do not use copper, lead, zinc, or tin metal materials in liquid end parts. These materials are prohibited in rechargeable battery production. In some cases, substitute materials may be used for the drive part. Please inquire for details. We can provide material details for each part.

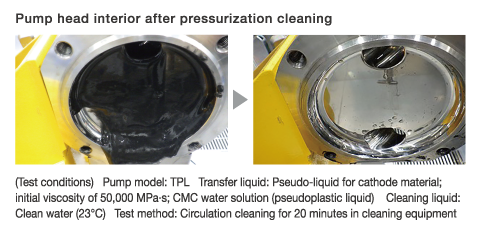

Outstanding cleaning results (inline cleaning)

Liquid end part structures are designed to avoid unevenness and dead space, so as to prevent adhesion of chemical liquids. As well, because pressurization is possible, booster pumps can be used to perform high-speed cleaning.

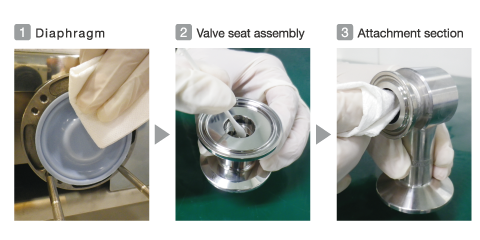

Easy disassembly and cleaning

The pump head is secured with eye bolts and the piping with sanitary clamps for easy disassembly (with sanitary specifications). Does not require specialized tools or adjustments when assembling .

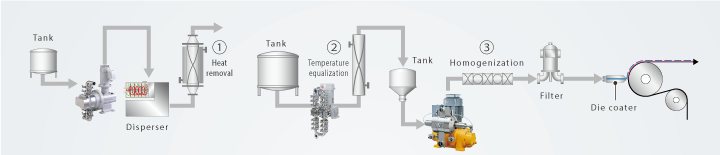

Inline and continuization proposals for rechargeable battery production processes

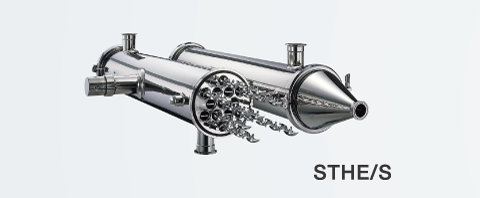

Combine our Smoothflow pump, a static mixer that performs mixing inside the pipe, and a heat exchanger that controls temperatures to achieve more efficient production and improved product quality.

①Immediately and efficiently remove dispersed heat

Excellent at heat exchange for high-viscosity liquids. Boosts heat exchange efficiency by 3 to 5 times. Cooling takes place during transfer, which can dramatically shorten cooling times.

②Slurry liquid temperature is precisely controlled and equalized.

Equalizing coating solution temperature (to within +/- 0.5°C) Reduces risk of shutdowns caused by core material rupture due to die thermal expansion.

③Eliminates slurry sedimentation and achieves homogenization

Eliminates sedimentation in the slurry and helps ensure that coating solutions remain uniform. Eliminating inconsistency within the coating solution helps improve product quality

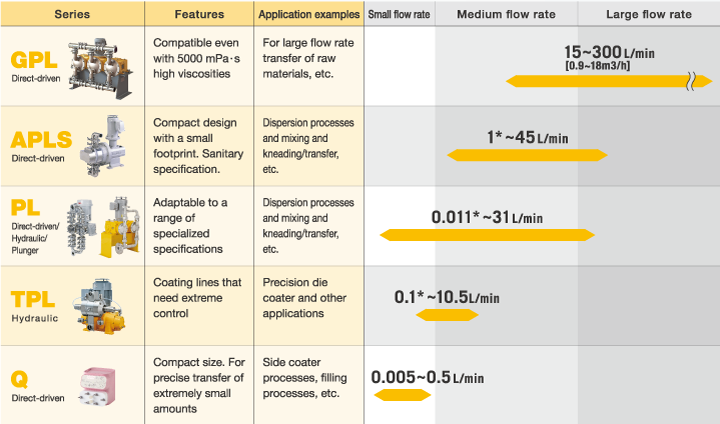

Smoothflow Pump Lineup

Specifications are flexible, so we can adapt our pumps to accommodate liquid characteristics, application, and installation environment.We have other pumps suitable for a range of liquid types.

- GPL

- Max. discharge volume

- 150L/min

- Max. discharge pressure

- 0.3MPa

- Direct-Driven Type

- High Capacity

- APLS

- Max. discharge volume

- 1~45L/min

- Max. discharge pressure

- 0.5MPa

- Direct-Driven Type

- Medium Capacity

- Sanitary

- PL

- Max. discharge volume

- 0.01~31L/min

- Max. discharge pressure

- 10MPa

- Direct-Driven Type

- Precision

- Plunger Type

- Hydraulic

- High-Pressure

- Trace Amount Injection

- TPL

- Max. discharge volume

- 0.1~30L/min

- Max. discharge pressure

- 15MPa

- Hydraulic

- High-Precision

- Ultra High-Pressure

- Trace Amount Supply

- Q

- Max. discharge volume

- 0.005~100mL/min

- Max. discharge pressure

- 3.0MPa

- Direct-Driven Type

- Precision

- Trace Amount Supply

Liquid Solutions Center

Liquid Solutions Center is a facility where we perform testing with advanced analyzers using liquids that are actually used in battery/electrode materials and recreating the process similar to the usage environment.