Topics|Smoothflow pumps Smoothflow Pump Strengths by Process and implementation examples for Rechargeable Battery Materials

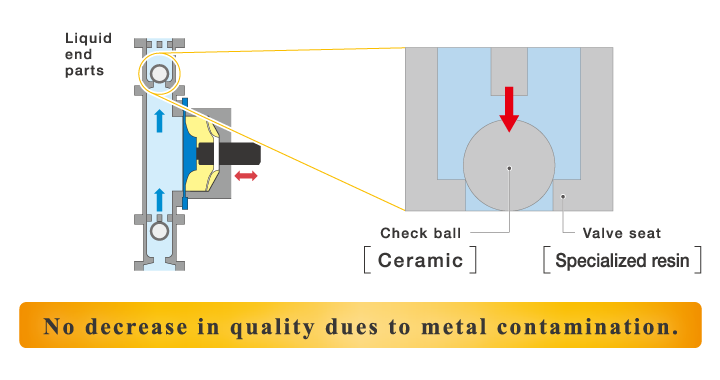

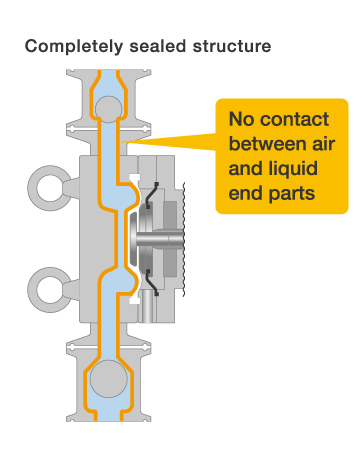

We reduce manufacturing defects with a contaminant-free structure that avoids using metal materials unrated for liquid end parts.

Material Restrictions

Our Smoothflow pumps do not use copper, lead, zinc, or tin metal materials in liquid end parts. These materials are prohibited in rechargeable battery production. There are no sliding parts or shaft seals, so wear is avoided. The seal surface on which the check ball sits has a very small contact area and low contact frequency. Ceramic and resin are used for these parts. This helps ensure quality.

In some cases, substitute materials may be used for the drive part. Please inquire for details. We can provide material details for each part.

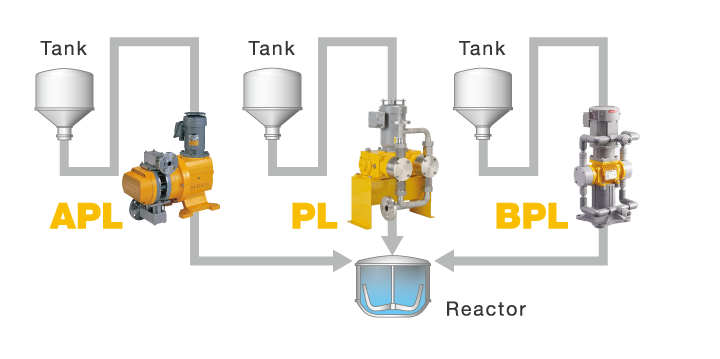

Carhode Material

Crystallization reaction and transfer process Stable transfer without pulsation

- Sustains high transfer accuracy over long time periods

- Flow meters provide accurate measurement/monitoring capabilities

- Accessories such as air chambers are not required, reducing maintenance load

Transfer liquid examples::Ternary materials, alkaline chemicals, etc.

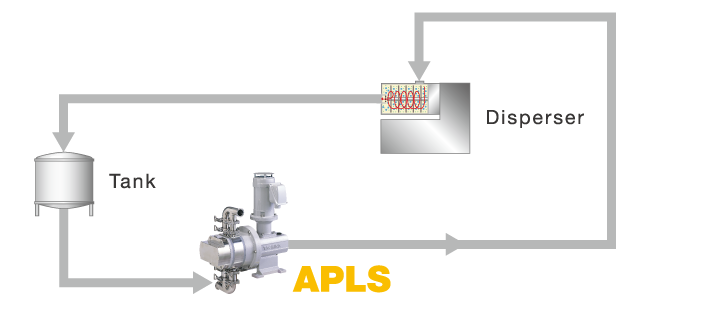

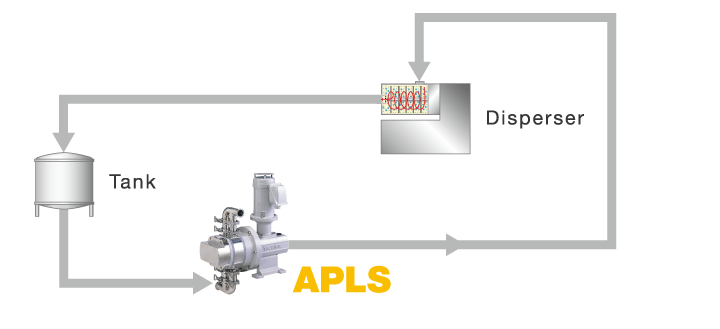

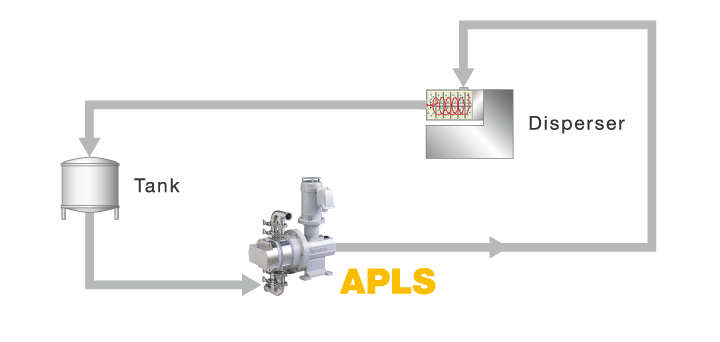

Dispersion process Improved grain size distribution

- No bead unevenness, delivers sharp grain size distribution

- No air chamber is required, so there are no worries about uneven concentrations due to retention

- No metal contamination even with highly abrasive slurries.

Transfer liquid examples:Active material + CNT, etc.

Anode Material

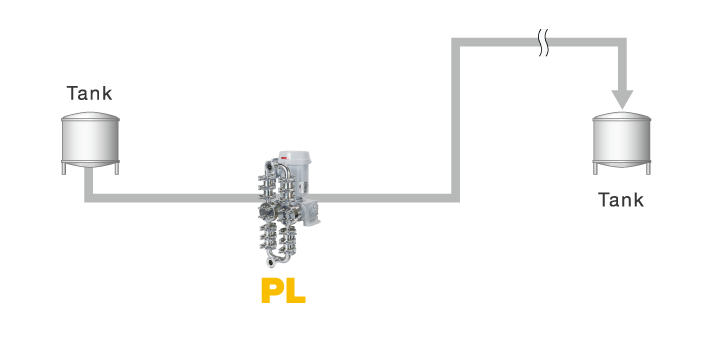

Transfer process Stable transfer without pulsation

- Long-distance transfer possible even for high-viscosity liquids

- No metal contamination even with highly abrasive slurries.

- Flow meters provide accurate measurement/monitoring capabilities

Transfer liquid examples:Graphite materials, solvents, etc.

Dispersion process Improved grain size distribution

- No bead unevenness, delivers sharp grain size distribution

- No flow rate decrease due to wear

- No air chamber is required, so there are no worries about uneven concentrations due to retention

Transfer liquid examples:Graphite materials, etc.

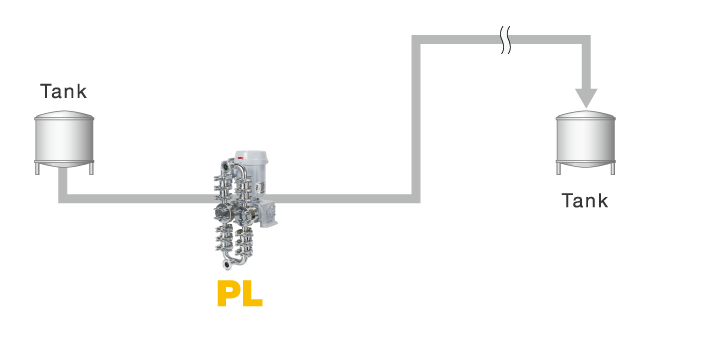

Separator

Transfer process Stable transfer without pulsation

- Sustains high transfer accuracy over long time periods

- Flow meters provide accurate measurement/monitoring capabilities

- No metal contamination even with highly abrasive slurries.

- Long-distance transfer possible even for high-viscosity liquids

Transfer liquid examples:Ceramic slurry, etc.

Dispersion process Improved grain size distribution

- No bead unevenness, delivers sharp grain size distribution

- Improved dispersion efficiency helps boost productivity

- Flow rate does not decrease even with highly abrasive slurries; maintains stable transfer over long periods of time

Transfer liquid examples:Ceramic slurry, etc.

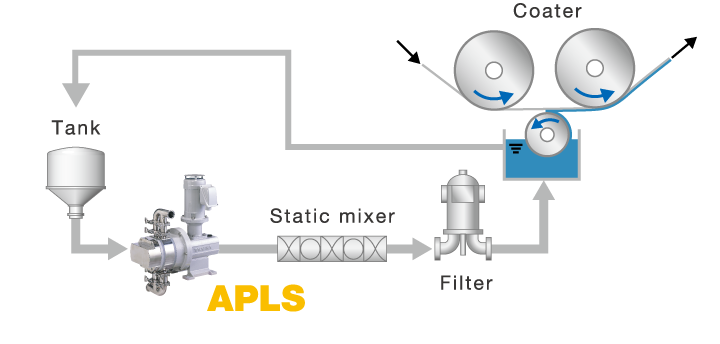

Coating process Precision transfer for precise thin film coating

- No effect from liquid viscosity fluctuations or pressure fluctuations caused by filters

- Maintains initial performance for a long period of time

- No particle aggregation or bubbling caused by the pump

Transfer liquid examples:Ceramic slurry, etc.

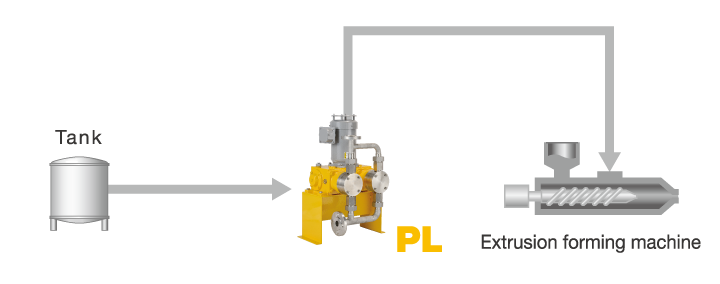

Injection process High-pressure injection into extrusion forming machine

- No pulsations and no injection fluctuations

- Simple disassembly and cleaning.

- Can be used for high-temperature liquids up to 120°C (inquire for details)

Transfer liquid examples:Oil-like liquids

Contributes to consistent quality in rechargeable battery production

Highly stable liquid transfer

No pulsations means accurate liquid transfer. Flow meters provide measurement and monitoring capabilities.

No adverse effects from pressure/viscosity fluctuations

Delivers stable discharge performance even as pressure and viscosity change.

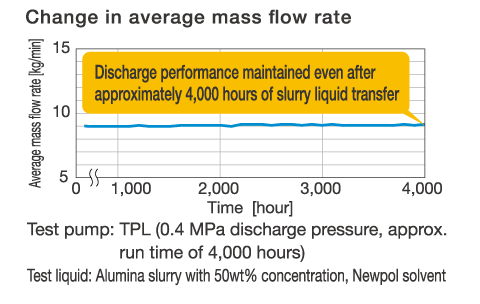

Long-term stability even with highly abrasive slurry liquids

The structure has excellent wear resistance, which means that even with highly abrasive slurry liquids, flow rate does not decrease due to pump parts wear or leakage.

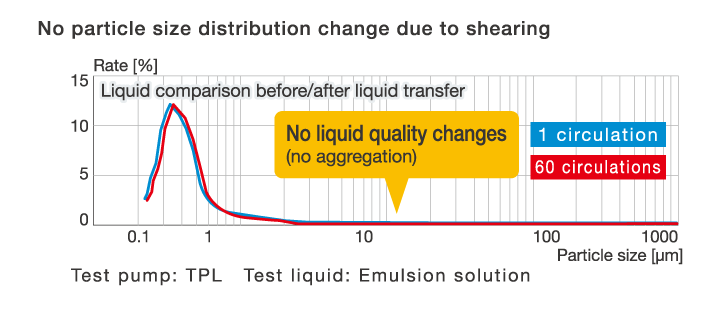

No liquid quality changes

Because liquids are not stirred and excessive localized pressure is not applied, there is no risk of liquid quality changes due to shear, abrasion, or temperature. There is no slurry re-clumping or gelation, nor temperature increases in the liquid caused by the pump.

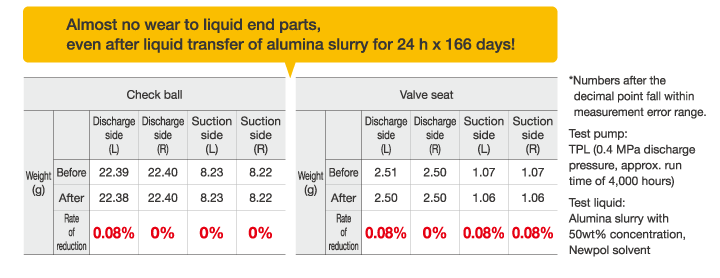

Contamination-free

The liquid end parts have no mesh parts, which means that pump parts experience almost no wear, even when transferring abrasive slurries. Contamination risks can be reduced.

No bubbles

No shaft seals means that air is not drawn in from the outside. The liquid does not contact the air, meaning no dangerous gases are generated.

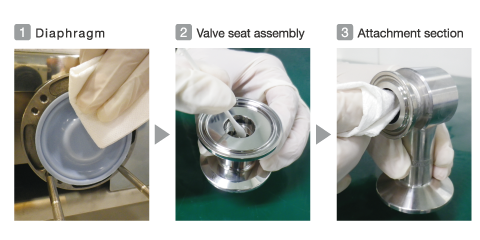

Easy disassembly and cleaning

The pump head is secured with eye bolts and the piping with sanitary clamps for easy disassembly (with sanitary specifications). Does not require specialized tools or adjustments when assembling .

Proposal for Dilution Installation in Production Process for Precursor Material

Perform inline dilution within your own company of sodium hydroxide and sulfuric acid required in the production process

Dramatically cut costs with in-house dilution! Sodium hydroxide dilution system

- Complete dilution in the time it takes to unload from the tanker truck

- Dramatically smaller footprint, as there is no need for dilution tanks or agitators, etc.

- Capable of high-accuracy dilution with concentration accuracy of +/- 0.1%

A sulfuric acid dilution system that continuously produces dilute sulfuric acid at specified concentrations

- Dilution performed by inline mixer enables safe and continuous dilution production

- Dilution heat is also dispelled inline, enabling short dilution times

- Easy to produce the concentrations you want

Smoothflow Pump Lineup

Specifications are flexible, so we can adapt our pumps to accommodate liquid characteristics, application, and installation environment.

- GPL

- Max. discharge volume

- 150L/min

- Max. discharge pressure

- 0.3MPa

- Direct-Driven Type

- High Capacity

- APLS

- Max. discharge volume

- 1~45L/min

- Max. discharge pressure

- 0.5MPa

- Direct-Driven Type

- Medium Capacity

- Sanitary

- PL

- Max. discharge volume

- 0.01~31L/min

- Max. discharge pressure

- 10MPa

- Direct-Driven Type

- Hydraulic

- Plunger Type

- Precision

- High-Pressure

- Trace Amount Injection

- BPL

- Max. discharge volume

- 0.05~80L/min

- Max. discharge pressure

- 1.0MPa

- Direct-Driven Type

- High Capacity

- Q

- Max. discharge volume

- 0.005~100mL/min

- Max. discharge pressure

- 3.0MPa

- Direct-Driven Type

- Precision

- Trace Amount Supply

Liquid Solutions Center

Liquid Solutions Center is a facility where we perform testing with advanced analyzers using liquids that are actually used in battery/electrode materials and recreating the process similar to the usage environment.