Basics|Precision pumping technology 6-1. Smoothflow Pump

This course has so far discussed that diaphragm pumps always come with pulsation.

In fact, text books that explain diaphragm (reciprocating) pumps describe them as always having pulsation. However, this is not a complete explanation--actually, it's missing "when the pump head is a single head."

This means that if a diaphragm pump design featured a dual or triple serial pump head configuration, pulsation can be eliminated.

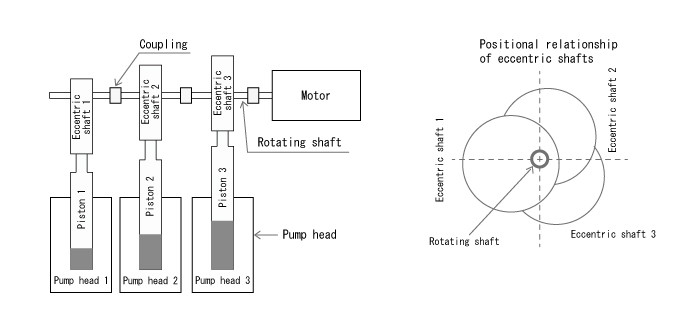

Triple Smoothflow Pump Configuration

Let's review Fig. 1 in "4-1. Air Chamber". It was explained that the gaps in the figure need to be filled in to eliminate pulsation. One of the methods of filling in the gaps was using an air chamber.

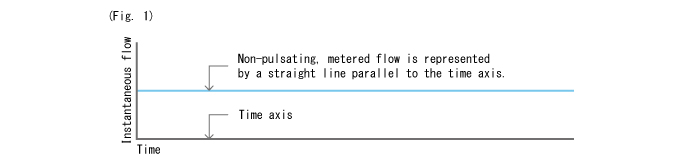

Note here that "no pulsation" means that the line representing the instantaneous flow rate in the graph is a straight line parallel to the time axis.

Non-pulsation can be achieved by somehow creating a flow property such as that shown in Fig. 1.

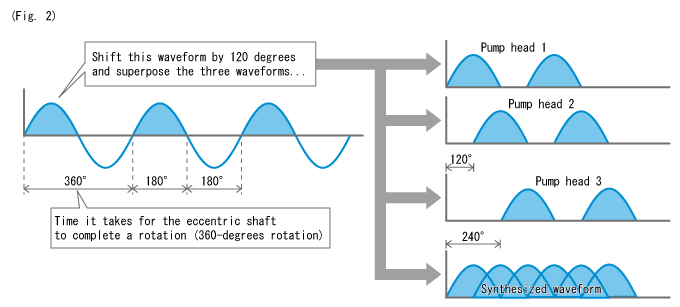

By using three eccentric axes to slightly shift the drive timing (specifically, 120 degrees), the synthesized waveform from the liquid discharges from the three pump heads can be made close to a straight line.

You can see from above that a state close to non-pulsation can be attained by shifting the movement of the eccentric shaft by 120 degrees. This must be a 120-degrees shift--non-pulsation cannot be achieved by a 90 or 180-degrees shift.

Can Non-Pulsation Be Attained by Using Three Separate Pumps?

Having three pumps means that there are three motors used in the system.

In such a case, non-pulsation can be achieved if all of the motors' rotational speeds are exactly the same--however, in reality they are slightly different.

For this reason, even when the pumps are driven at their own given timing at the beginning of the operation and pulsation is suppressed, the waveforms will eventually deviate.

Which is to say that pulsation starts cropping up. To make matters worse, compared to a single pump head configuration, separate multiple pump heads can create a stronger pulsation.

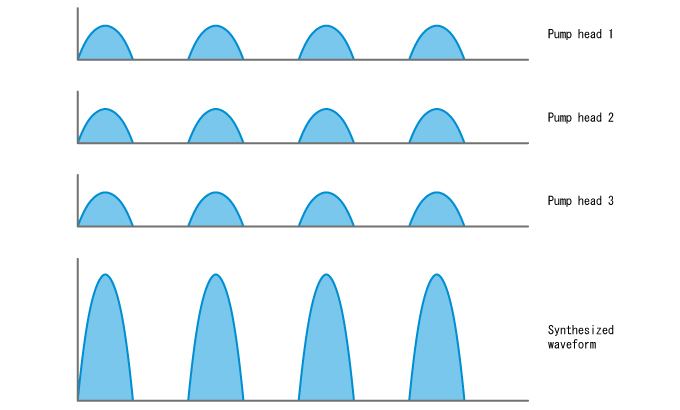

For instance, if the drive timing of the three pumps completely coincide (synchronize), the pulsation reaches its maximum level as shown in the figure below.

In this state, the extremely strong pulsation will clearly bring about overfeeding and excessive pressure.

From the above, you can conclude that achieving non-pulsation is in nature impossible using three pumps.

- * Ignoring cost, theoretically speaking, non-pulsation can be achieved by controlling the rotational speed of the motor.

Smoothflow Pump

TACMINA developed a mechanism that can eliminate pulsation using only the pump, taking advantage of its proprietary liquid transfer technique.

The Smoothflow Pump adopts a specially-formed eccentric cam that produces a continuous flow with no pulsation, achieving non-pulsating metered-precision liquid transfer.

While retaining the benefits of a diaphragm pump, including good quantitative performance and compatibility with a wide range of chemicals, the Smoothflow Pump can resolve the issues of liquid transfer.

Working Principle

- (1)

Speed of the motor rotation is reduced using a reducer.

- (2)

Rotary motion is converted into the reciprocating motion of the pump shaft using the eccentric mechanism.

- (3)

When the diaphragm at the end of the pump shaft moves in a reciprocating motion, the volume inside the pump head increases and decreases.

- (4)

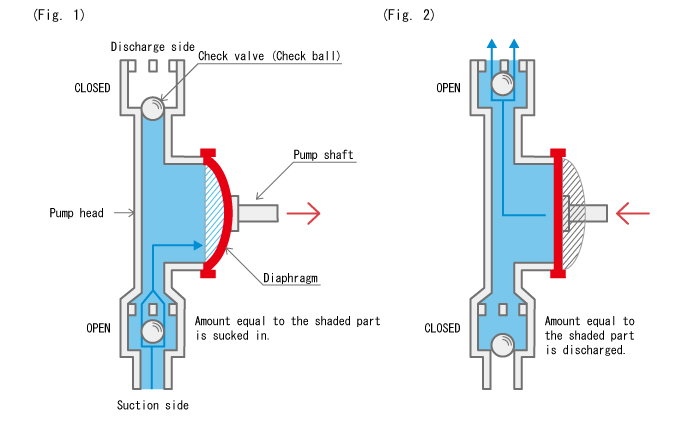

When the diaphragm moves out, negative pressure develops inside the pump head. When this occurs, the ball check valve at the discharge side closes the flow path as shown in Fig. 1, preventing the chemical from flowing back from the discharge-side pipe. On the other hand, the ball check valve at the suction side opens the flow path, which enables chemical to flow into the pump head from the suction side.

- (5)

Next, when the diaphragm moves inward, positive pressure develops inside the pump head. The ball check valve at the suction side closes the flow path while the discharge side opens, discharging chemical to the discharge side. (Fig. 2)

Dual Pump Non-Pulsation Mechanism

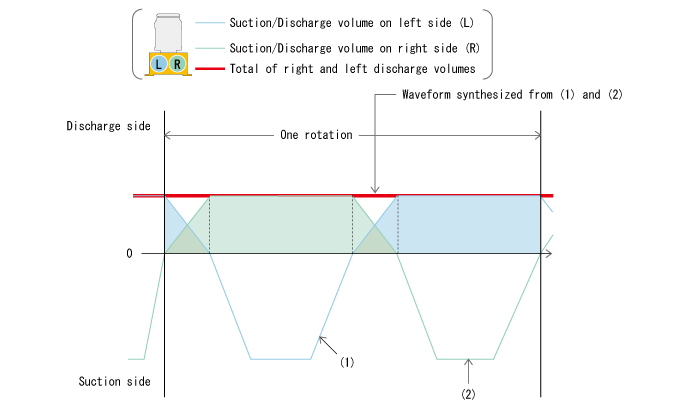

The discharge property of one pump head is made into a trapezoidal waveform as shown in (1) below by using a special-formed eccentric cam for the eccentric mechanism. The other pump head is driven 180 degrees shifted as shown in (2) below. The synthesized waveform shows a constant flow.

The suction side (bottom half of the figure) has pulsation.

TACMINA's Smoothflow Pump adopts a special-formed eccentric cam that generates a continuous constant flow without pulsation. The series features a wide-ranging lineup to accommodate diverse process needs.

More...