Basics|Precision pumping technology 4-3. Precautions for Using the Air Chamber (1/2)

Using an air chamber is the easiest way to reduce pulsation. However, it is not completely flawless. As is the case with any method, when adopting equipment, we need to understand the disadvantages, precautions, and limitations of the equipment in addition to its advantages.

Air chambers are not an exception, and have their own disadvantages and points that need to be considered.

Regular Supply of Air Is Required

Although the amount is slight, air does dissolve into liquid. The higher the pressure, the more it dissolves into the liquid. This is called Henry's law. If there is no inflow or outflow of liquid inside a sealed container, the liquid is saturated with gas after a certain amount of air has dissolved into the liquid, and the air does not escape.

For example, under a pressure of 0.5 MPa, the amount of air corresponding to that pressure dissolves into the liquid. This condition is called saturation. Once the liquid is saturated with air, the air remains until the liquid is replaced.

However, in the case of an air chamber, unlike the case with the sealed container above, the liquid is replaced. As long as the pump is operating, unsaturated liquid continuously enters the air chamber.

This causes the air inside the air chamber to rapidly be taken up into the liquid. This indicates that the air inside the air chamber will gradually decrease and will finally be exhausted.

What Happens When There Is No More Air in the Air Chamber?

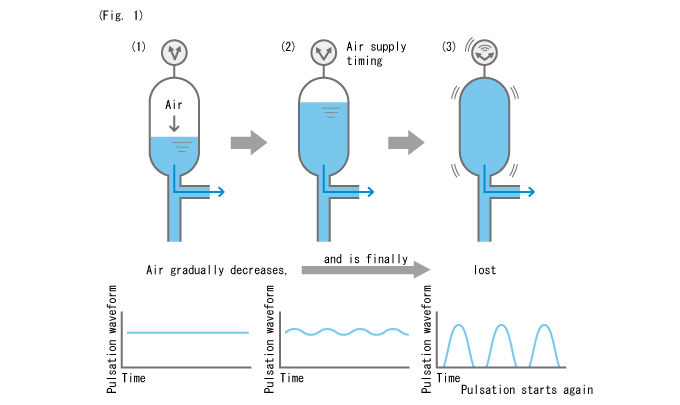

When air is completely lost from the air chamber, it functions as simply a part of the piping--liquid will again be discharged from the discharge port with pulsation. When that occurs, unwanted actions associated with pulsation, as mentioned in "2-3. Pulsation: Inertial Resistance" appear and create problems. (See Fig. 1) And so there is the need to regularly supply air to the air chamber.

[State of air chamber]

- (1) Normal: Chamber has sufficient air, and only small fluctuations appear on the manometer.

- (2) Cautionary: Air inside chamber decreases, and larger fluctuations appear on the manometer.

- (3) Dangerous: No more air is present inside the chamber, and pulsation and piping vibration start. You must immediately stop the pump and supply air to the air chamber.

Continuing operation in this state can lead to damage to the pump and/or piping.

When Do You Supply Air?

Considering the states of air chamber above, you will need to supply air in state (2) in Fig. 1. Specifically, it is the point when the swing of the needle of the manometer becomes about double the normal swing.

However, there is no uniform answer to the question at what interval air should be supplied.

More air dissolves into liquid at higher pressures. This indicates that different pressures inside the air chamber can change the time it takes for air to run out.

Apparently, that time also depends on the amount of air. The type of liquid can also affect the solubility of air. As we have studied here, it is very difficult to temporally determine the interval for supplying air.

TACMINA's Smoothflow Pump can provide continuous metered transfer without an air chamber. No need for burdensome air chamber recharge--eliminate the risk of chemical splattering from air chamber bursting or leakage from piping vibrations.

More...