Basics|Precision pumping technology 4-2. Working Principle of Air Chambers

Working Principle of Air Chambers

The working principle of an air chamber is essentially the same as the injection syringe in the examples given. What is different is that the piston is replaced with the "liquid" sent from the pump. Both the piston and liquid are not compressed like air, so they can be treated as being the same. (Strictly speaking, liquid can also be compressed under high pressure—however, it will not be compressed by the pressures that a typical diaphragm pump can apply.)

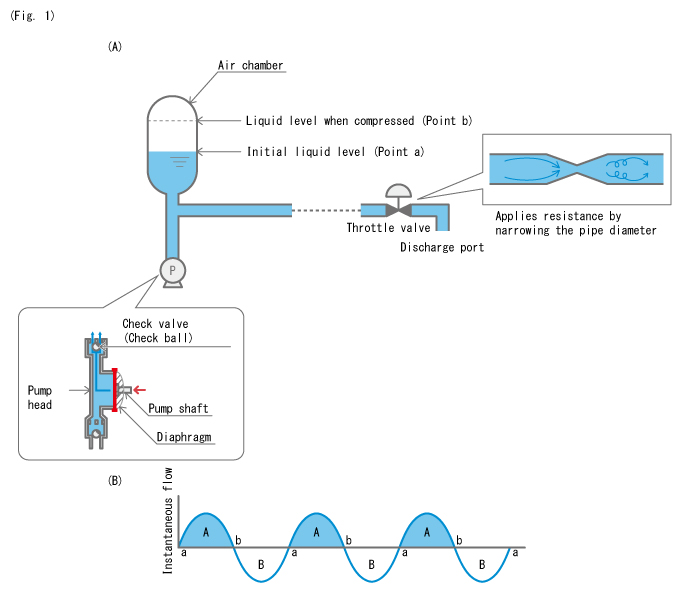

Let's consider the working principle of an air chamber and the characteristic pulsation of a diaphragm pump upon discharge using Fig. 1.

The A parts show a discharge waveform (liquid is actually discharged), and the B parts show a suction waveform (liquid is sucked into the pump head and is not discharged). Points "a" in (B) coincide with the initial position in (A), namely the bottom dead center of the piston (diaphragm). Points "b" coincide with the completion of compression, which is the top dead center of the piston (diaphragm).

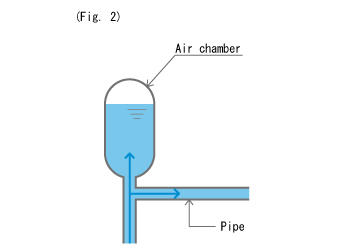

First, let's think about when the pump is started up and the piston (diaphragm) moves from point a to b (discharge cycle). In this case, the discharged liquid branches into two directions as shown by arrows in Fig. 2.

The ratio of branched liquid depends on the pressure loss (resistance) in the piping. If the resistance in the piping is large (i.e. pipe diameter is small), more liquid enters the air chamber, and little flows into the pipe. On the other hand, if the resistance in the piping is small (i.e. pipe diameter is large), almost no liquid enters the air chamber, and most of the liquid flows into the pipe.

Pulsation Decreases When the Branched Liquid Volumes Are the Same

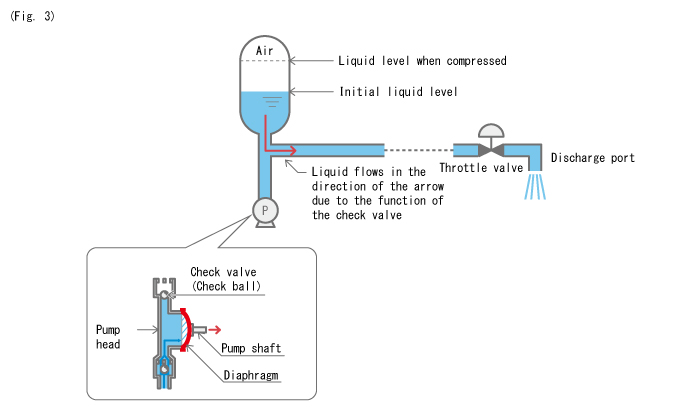

What happens when the piston (diaphragm) moves from point b to a? From point b to a, the piston (diaphragm) is in a suction cycle. Therefore, the check valve on the discharge side is closed, and no backflow occurs from the air chamber or pipe. (Fig. 3)

Now, go back to Fig. 2 of "4-1. Air Chamber" in the previous section. In the case of an injection syringe, the piston returns to its original position due to the force applied by the compressed air. In an air chamber, liquid is pushed back.

For this reason, liquid is discharged from the pipe during the pump's suction cycle.

Which means that the gaps in Fig. 1 of "4-1. Air Chamber" is filled in, and as a result, pulsation diminishes.

However, in order to significantly reduce pulsation, the amount of liquid flowing into the pipe and the amount flowing into the air chamber must be the same at the point of the liquid flow branching. The throttle valve is required on the discharge side for the adjustment of the branched liquid volumes.

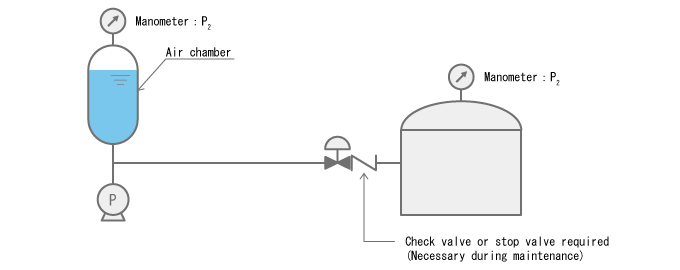

In general, pulsation rate is minimal when the P2 value on the manometer (Average pressure: Absolute pressure) is adjusted to double the P1 value in the figure below.

- * The manometer on top of the air chamber is useful for the adjustment of pulsation rate in addition to the inspection for abnormal pressure.

TACMINA's Smoothflow Pump can provide continuous metered transfer without the use of an air chamber. While keeping the advantages of a diaphragm pump, our Smoothflow Pumps can resolve your dissatisfaction with liquid transfer.

More...