Basics|Precision pumping technology 3-2. Solutions to Overfeeding 1: Reducing the Inertial Resistance

Reducing the Inertial Resistance

The inertial force (inertial resistance) in a metered pump can be expressed by the following equation:

Pi = 2 x 10-6 x (D/d)2 x (N/60)2 x S x L x γ

Let's break down this equation and look at the individual factors.

The factors will be as follows for plunger pumps. In the case of standard diaphragm pumps, the effective diaphragm diameter is used instead of the plunger diameter (D) below. The rest is exactly the same.

| Item | Description | Unit |

|---|---|---|

| Pi | Pressure from the liquid's inertial force | MPa |

| 2 x 10-6 | Conversion factor | N/A |

| (D/d)2 | Square of (Plunger diameter / Hose diameter) | (cm/cm)2 |

| (N/60)2 | Square of (Strokes per minute / 60) | (spm/60)2 |

| S | Stroke length | cm |

| L | Hose length | cm |

| γ | Liquid density | g/cm3 |

- Proportional: a) stroke length, b) hose length, c) liquid density

- Proportional to the square: d) plunger diameter, e) strokes per minute

- Inversely proportional to the square: f) Hose diameter

Next, let's look at the meaning and its impact for each item.

Elements That Affect the Inertial Resistance and the Degree of Their Impact (1)

Symbol a: Stroke length

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Proportional (Example) |

Shorten the stroke length |

|

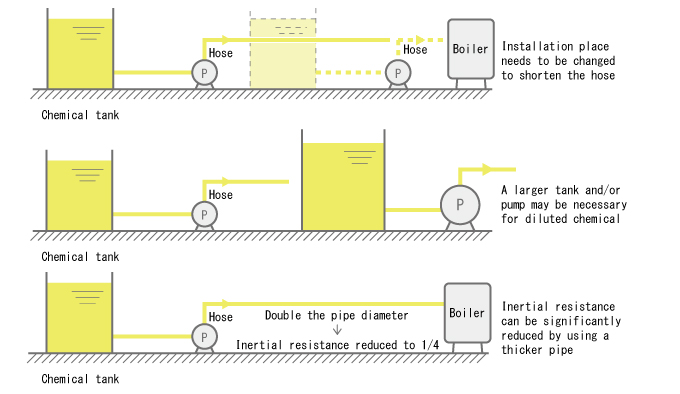

Symbol b: Hose length

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Proportional (Example) |

Shorten the hose |

|

Symbol c: Liquid density

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Proportional (Example) |

Dilute the chemical |

|

Elements That Affect the Inertial Resistance and the Degree of Their Impact (2)

Symbol d: Plunger diameter

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Proportional to the square (Example) |

Changing the plunger diameter is not practical |

|

Symbol e: Stroke speed

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Proportional to the square (Example) |

Control the rotation speed using an inverter, etc. |

|

Symbol f: Inner diameter of hose

| Impact | How to reduce inertial resistance | Advantages and disadvantages |

|---|---|---|

|

Inversely proportional to the square (Example) |

Increase the hose diameter |

|

onsidering the above chart, the most effective way is "f."

Replacing the hose with a thicker one is relatively easy to do; additionally, the effect is squared in value without the need to consider any changes in the discharge volume. However, to prepare for the disadvantages, it is still important to consider the pump layout and the inertial resistance before installing the metered pump.

TACMINA's Smoothflow Pump is a diaphragm pump with no pulsation, which relieves it from the impact of inertial resistance. Saves you costs by supporting narrower and longer pipes.

More...