Basics|Precision pumping technology 3-1. A Common Problem Caused by Overfeeding

Larger than specified discharges are a common problem experienced by many operations. The most common cause is overfeeding.

Example: In an application where boiler compound is supplied to the boiler, the discharge is at more than double the rated volume.

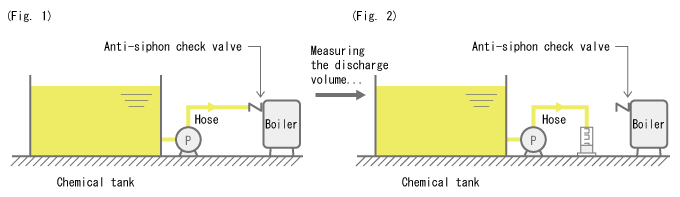

- Fig. 1 Normally, the chemical is supplied to the boiler via an anti-siphon check valve

- Fig. 2 Measuring the discharge volume by removing the hose while leaving the anti-siphon check valve on the boiler

The problem was that the discharge volume was measured without connecting the anti-siphon check valve. In other words, overfeeding occurred because there was nothing counteracting the inertial force of the liquid (in this system, the anti-siphon check valve). In a case as shown above, the anti-siphon check valve must be connected to the end of the hose when measuring the discharge volume.

Furthermore, you must pay attention to the inner diameter and the length of the pipe, as the smaller the inner diameter of the pipe and the longer the pipe, the greater the inertial resistance will be.

One of the laws of physics is the equation F = mα. The acceleration α is a product of force F and mass m. The key point here is that, if the acceleration is the same, the force gets larger the greater the mass becomes.

Applying this to the hose of the pump, the greater the mass (weight) of the liquid in the hose, the force (inertial force) becomes larger. That is, a longer hose accommodates more liquid, which makes it larger in mass, and thus holds a greater inertial force.

In conclusion:

"In an application where an anti-siphon check valve is used, overfeeding is likely to occur when the inertial force exceeds the set pressure of the anti-siphon check valve."

TACMINA's Smoothflow Pump is a diaphragm pump with no pulsation, which relieves it from the impact of inertial resistance. Completely eliminate all overfeeding problems.

More...