Basics|Precision pumping technology 2-1. Pulsation: What Is Pulsation?

Pulsation

Problems with diaphragm pumps can be avoided to a large extent by understanding pulsation.

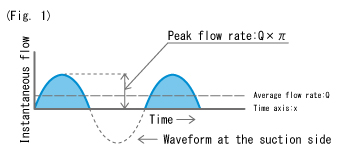

We already learned in the previous section that the sine curve shown in Fig. 1 is the discharge waveform of a diaphragm pump. Now, let's look at why the discharge waveform takes this particular form.

Diaphragm pumps are commonly driven by a spring return system or a crank drive feature. Here, we will explain pulsation using the spring return system as an example.

Motors are typically used to drive diaphragm pumps.

The reciprocating motion of the piston is generated by the high-speed rotation of the motor, which is transferred to the rotating shaft via a reducer, also using the eccentricity between the eccentric shaft and rotating shaft.

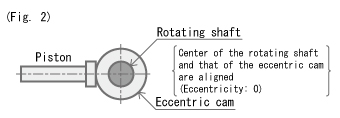

Fig. 2 shows a case where the center of the rotating shaft and that of the eccentric cam are aligned. This means that the eccentricity is zero. In this case, the eccentric cam does not affect the piston movement in any way, and the piston does not move at all.

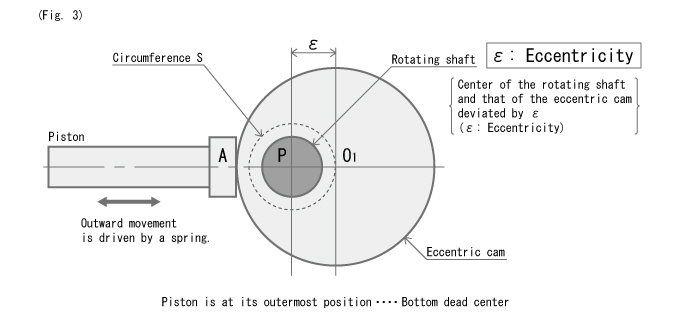

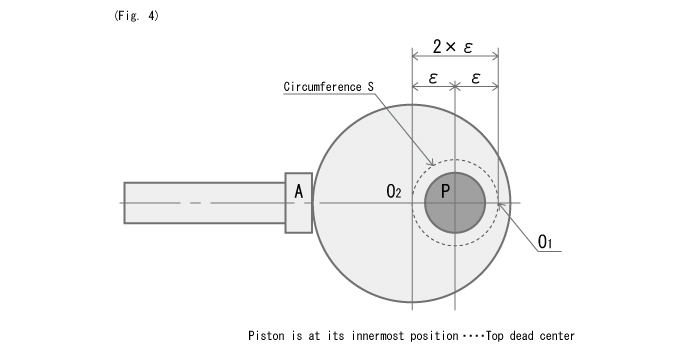

Next, let's think about cases where the center of the rotating shaft and that of the eccentric cam are not aligned as shown in Fig. 3 and Fig. 4. (ε: epsilon)

In this case, the eccentric cam center O moves along Circumference S as the rotating shaft turns.

Which means, the eccentric cam turns while swinging outward.

Looking at Fig. 3 and Fig. 4, you can see that the piston is moving back and forth, traveling the equivalent of the distance between Points O1 and O2.

Specifically, the reciprocating motion of the piston travels 2 x ε, which is double the eccentricity. For example, if the eccentricity is 4 mm, the reciprocating motion distance (stroke length) will be 8 mm.

Here, note that because Point O moves along Circumference S, the speed at which the stroke length reaches its max value from 0 is not constant.

When this piston speed is shown in a graphic form, you will find a sine curve.

The piston picks up speed and then slows down.

Since liquid is sucked in and discharged with this piston movement, the speed of liquid movement also displays sine curve properties. (The actual waveform is not a perfect sine curve due to frictional force that works between the liquid and pipes, etc.)

The liquid flows inside the pump and through pipes with a cyclic flow rate.

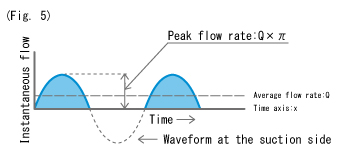

Now, let's look at the waveform in Fig. 5 again.

The solid-line curve shows the discharge waveform while the dotted line represents the suction waveform. What this indicates is that a flow with sine curve properties occurs at both the discharge and suction sides of a reciprocating pump.

This graph also shows that suction and discharge occur alternately.

This is pulsation, a key characteristic of diaphragm pumps.

TACMINA's Smoothflow Pump is the only diaphragm pump that ensures continuous metered supply with no pulsation. Metered liquid transfer is possible with high accuracy and no pulsation.

More...