Basics|Precision pumping technology 1-1. Diaphragm Pump: What Is a Diaphragm Pump?

Working Principle of Diaphragm Pumps

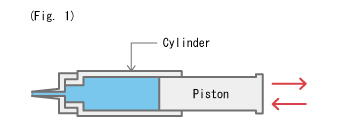

First, imagine that painful injection. An injection syringe is in fact the basic form of a diaphragm pump.

When the piston is pulled back as shown in Fig. 1, the liquid is pulled into the cylinder.

When the piston is pushed forward, the liquid is discharged through the injection needle at the tip of the cylinder.

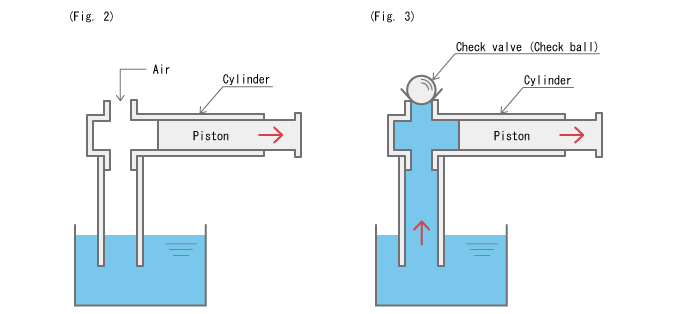

The liquid enters and exits from the same point with an injection syringe, but let's look at a model that has separate entry and exit points.

(In this example, the entry and exit flow paths are both circular.)

Would the cylinder suck in liquid when the piston is pulled outward in Fig. 2?

The answer is no. Even when the piston is moved outward, only air is sucked in from the upper side of the cylinder without pulling up the liquid.

Now, we will place a spherical check valve on the hole where the air entered in Fig. 2.

Then, as shown in Fig. 3, air no longer flows in, and negative pressure is generated inside the cylinder, which sucks up the liquid.

If the check valve is very light, some liquid may be discharged, but mostly it will return to the tank.

If the check valve is quite heavy, all of the water sucked up will return to the tank.

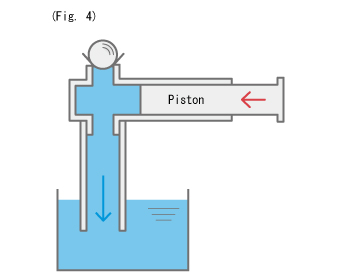

Next, let's press the piston. (Fig. 4)

If the check valve is very light, some liquid may be discharged, but mostly it will return to the tank.

If the check valve is quite heavy, all of the water sucked up will return to the tank.

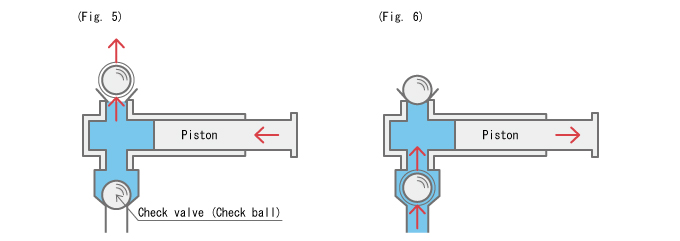

Now, we place another check valve, in the lower side of the cylinder in the direction that stops backflow.

In this case, due to the lower check valve the liquid inside the cylinder does not return to the tank, as shown in Fig. 5, and pushes the upper check valve up and flows out.

When the piston is moved outward, this time once the upper check valve closes, the lower side opens, and the liquid is sucked into the cylinder.

Note that there is no backflow from the upper side at this time. (Fig. 6)

As shown here, a check valve works to move liquid in one direction, which is a key function that is essential to a diaphragm pump (reciprocating pump).

Generally, a check ball is used as the check valve.

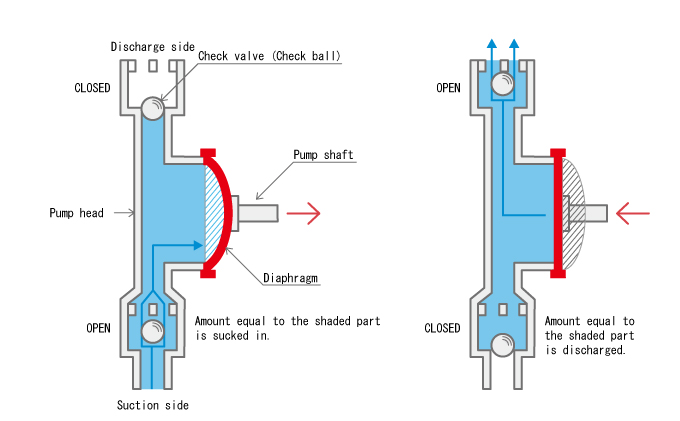

Structural Diagram of the Pump Head of a Diaphragm Pump

The above shows the principle of the suction and discharge by a diaphragm pump.

Characteristics of Diaphragm Pump

Based on the above working principle, diaphragm pumps have the following characteristics.

1. Liquid Flows With Pulsation

Because of its operating principle, liquid flows intermittently due to the alternation of suction and discharge. This is called pulsation, which makes diaphragm pumps fundamentally different from centrifugal pumps. (To be detailed later)

2. Once Liquid Enters the Cylinder by the Working of a Check Valve, It Always Flows Out From the Upper Side.

Therefore, even when significant pressure is applied to the discharge side (upper side), holding down the ball check valve, as long as the power (force pressing the piston) permits, the pressure inside the cylinder increases.

Theoretically speaking, in the case of closed operation, this means that the pressure inside the cylinder can increase infinitely.

However, before the pressure reaches infinity, the weakest parts near the pump, for example the cylinder or discharge-side piping, may burst or the motor driving the piston may burn out.

This is the reason why a relief valve and a thermal relay for the motor should never be left out when using a diaphragm pump.

3. Sealing of the Check Valve Is Critical

Sealing is compromised when dirt or foreign matter enters around the check valve. In such an event, the non-return function is disabled, which severely impairs pump performance in such a way that in some cases the pump stops discharging completely. The same condition can occur when the check valve or valve seat (the part that contacts the check valve to create a seal) is damaged.

If the check valve and valve seat are dry, air passing through the slight gaps between the irregular surfaces may affect sealing performance. (If the pump is above the tank: suction condition)

In such a case, wetting the check valve and valve seat with liquid improves sealing, making suction and discharge possible.

TACMINA's Smoothflow Pump is the only diaphragm pump that ensures continuous metered supply with no pulsation. Metered liquid transfer is possible with high accuracy and no pulsation.

More...