Use CasesTransferring butyllithium, an inflammable chemical, under high pressure

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

National university (graduate school of engineering)

Customer's Needs and Problems

A small volume of the chemical is supplied to a microreactor during tests of organic synthesis.

TACMINA's Solutions

We suggested that the customer use a Smoothflow Pump, and they agreed to this proposal.

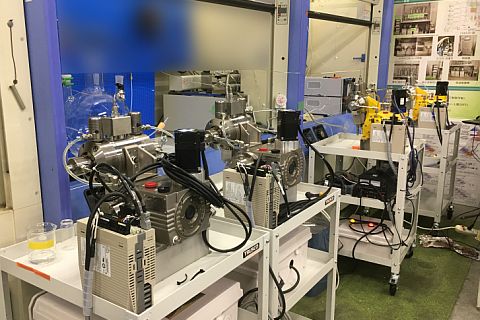

Image

Product

- TPL

- Max. discharge volume

- 0.1~30L/min

- Max. discharge pressure

- 15MPa

Ideal for process lines that require rigid control, such as optical film, IT, and high-purity pharmaceutical process lines

- Hydraulic

- High-Precision

- Ultra High-Pressure

- Trace Amount Supply