Use CasesImproving quality and ease of cleaning during the pigment dispersion process

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Pigment manufacturer

Customer's Needs and Problems

A bead mill is used to disperse materials in the pigment production process.

Depending on the liquid, the viscosity is approximately 5000 MPa·s, so a vane pump suited to high-viscosity liquid was used, which posed the following problems.

TACMINA's Solutions

We suggested that the customer use a pump with sanitary specifications from our Smoothflow Pump APLS Series.

We loaned the customer a demo machine, which they tested out and found that they could obtain the necessary results in terms of liquid transfer performance, cleanliness, and ease of cleaning. As such, the customer decided to switch to a Smoothflow Pump.

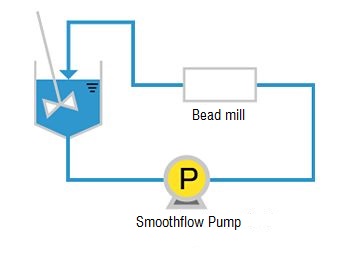

Flow Diagram

Product

- APLS

- Max. discharge volume

- 1~45L/min

- Max. discharge pressure

- 0.5MPa

Ideal for transferring food, cosmetics and materials that are prone to deterioration caused by handling, such as concentrated juice, food additives, mayonnaise, and lotions.

- Direct-Driven Type

- Medium Capacity

- Sanitary