Use CasesPreventing defective injection to obtain a constant residual chlorine concentration in a small water

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Local government (water department)

Customer's Needs and Problems

To supply safe tap water to a mountainous area, a small-scale water purification facility is used to filter and disinfect well water and discharge the purified water.

The residual chlorine concentration of the water tank was monitored and sodium hypochlorite was injected with a diaphragm pump, which posed the following problems.

TACMINA's Solutions

The sodium hypochlorite injection pump was changed to a DCLPW Series diaphragm pump, which is resistant against the gas lock phenomenon.

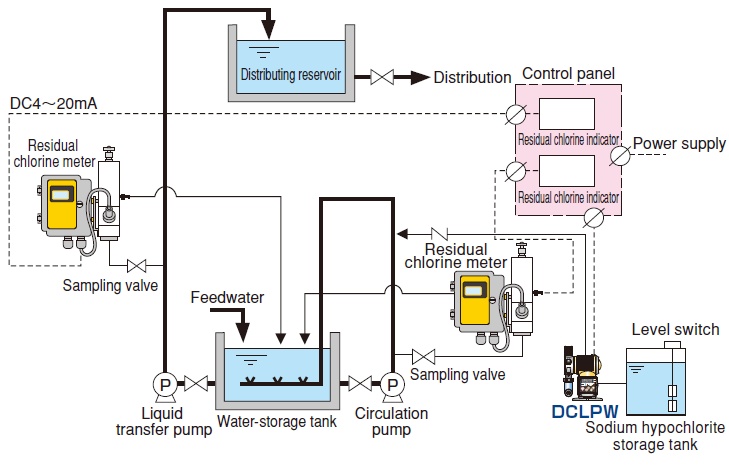

Flow Diagram

Product

- DCLPW・CLPW

- Max. discharge volume

- 90mL/min

- Max. discharge pressure

- 1.0MPa

- Digital Settings

- Multi-Functional