Use CasesImproving the operability of small-amount painting and the painting quality

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Consigned processing manufacturer

Customer's Needs and Problems

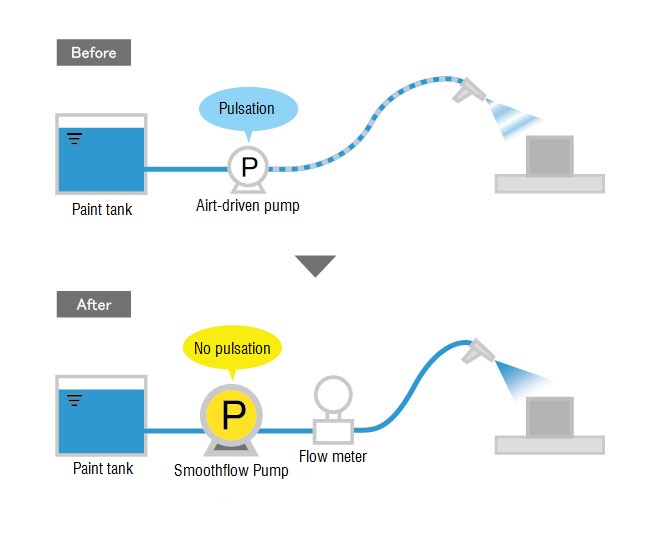

On a painting line for small parts, a pump is used to supply paint to the spray gun.

Conventionally, an air-driven diaphragm pump was used, which posed the following problems.

TACMINA's Solutions

We selected a Smoothflow Pump that matches the usage conditions and loaned a demo machine to the customer so they could evaluate it on-site.

As listed below, the effect of this pump exceeded the customer’s expectations, so they decided to switch to a Smoothflow Pump.

Flow Diagram

Product

- XPL

- Max. discharge volume

- 0.009~3L/min

- Max. discharge pressure

- 1.5MPa

For metered supply which required in a range of industries and applications including water treatment, coating, laboratory and production line

- Direct-Driven Type

- Trace Amount Injection