Use CasesStabilization of the concentration and reduction of operating costs when diluting sulfuric acid

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Chemical manufacturer

Customer's Needs and Problems

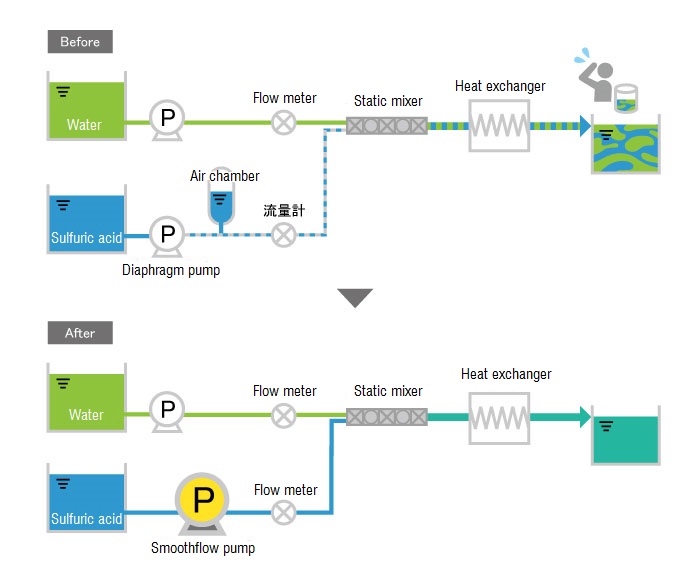

A diaphragm pump was used during the process of diluting concentrated sulfuric acid with water for industrial use.

To suppress the pulsation of the pump, an air chamber was installed on the piping, but this posed the following problems.

TACMINA's Solutions

Upon visiting the Pump Dojo mobile pump training facility, the customer learned of our Smoothflow Pumps, diaphragm pumps with no pulsation, and consulted with us regarding whether these pumps could be used to solve their problems.

The existing pump was replaced with a Smoothflow Pump and the air chamber was eliminated.

Flow Diagram

Product

- PL (Hydraulic Type)

- Max. discharge volume

- 0.01~31L/min

- Max. discharge pressure

- 10MPa

Ideal for High-Pressure injection of boiler-related chemicals and additive injection in resin molding process lines

- Plunger Type

- Precision

- High-Pressure

- Sulfuric acid diluter