Motor-Driven Metering Pumps What Is a Motor-Driven Metering Pump?

The rotary motion of the motor is converted to reciprocating motion by the eccentric cam mechanism which causes the volume displacement to transfer the fluid at a constant rate.

This type is used for applications in which durability is paramount such as those requiring 100% duty cycle or involving an important process, but where pulsation is not an issue.

Points on Model Selection

There are five pump head variations for Motor-Driven Pumps; select the one that best fits your application:

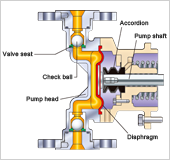

| Direct Drive Diaphragm Type | |

|---|---|

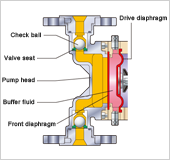

| Double Diaphragm Type |

A diaphragm rupture alarm sensor can be added. Depending on the choice of the buffer fluid in the intermediate chamber, it is possible to minimize the loss incurred in case of diaphragm rupture. |

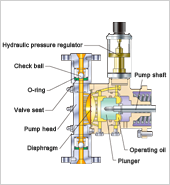

| Hydraulic Diaphragm Type |

This type uses operating oil, such as silicone, in the cavity between the diaphragm and the piston and features an embedded relief (safety) mechanism. This design is effective for fluids that should not be in contact with the open air. This High-Precision Type is capable of discharging a constant volume despite pressure fluctuations on the injection side. It is often used in High-Pressure applications such as petrochemical processing because this type is capable of discharging at a pressure higher than the Direct Drive Diaphragm Type or the Double Diaphragm Type. |

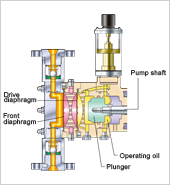

| Hydraulic Double Diaphragm Type |

Similar to the Double Diaphragm Type, this type shares many of the features of the Hydraulic Diaphragm Type with an additional diaphragm. This design does not require a bulkhead inside the pump chamber on the fluid transfer side, making it suitable for metering injection in High-Pressure lines of high viscosity fluids or slurries. |

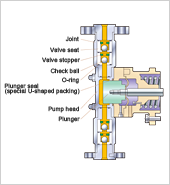

| Plunger Type |