Use CasesReducing chemical waste by measuring the accurate actual injection volume with a flow meter

| Liquid Type | |

|---|---|

| Process Type | |

| Industry | |

| Problem |

Customer

Local government (water purification plant)

Customer's Needs and Problems

The disinfectant (sodium hypochlorite) and the flocculant (polyaluminum chloride) are added.

A diaphragm pump is used for the chemical injection pump, which poses the following problems.

TACMINA's Solutions

The customer viewed a demo Smoothflow Pump and checked that measurement was possible with a flow meter.

Our technicians met with the customer multiple times until we were able to provide them with a device that is capable of the desired flow rate control.

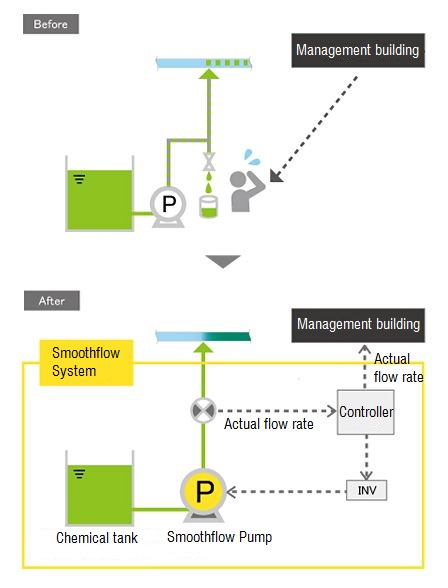

Flow Diagram

Product

- BPL

- Max. discharge volume

- 0.05~80L/min

- Max. discharge pressure

- 1.0MPa

Ideal for long-distance/high-pump-head transfer of various chemicals and fluids, such as water treatment chemicals and polymer coagulants

- Direct-Driven Type

- High Capacity